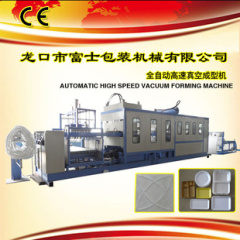

Full-auto Vacuum Forming Punching Cutting Counting and Stacking Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50set/year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | FS-CX |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Others |

| Brand Name: | FS |

| Power: | 150KW |

| Max forming area: | 1000mm*1100mm |

| Max forming depth: | 130mm |

| Forming mode: | Vacuum forming, press forming, mould forming, comprehensive forming |

| Forming pressure: | 20t (adjustable) |

| The production efficiency: | 10-15 seconds/mould |

| Weight: | 18T |

| Dimension: | 12m*2m*2.6m |

| Process material: | PS |

| Certification: | CE |

| Guarantee: | One year |

| Production Capacity: | 50set/year |

| Packing: | Export standard packing |

| Delivery Date: | About 50-60days |

Product Description

HIGH SPEED AUTOMATIC VACUUM FORMING AND CUTTING MACHINE

Machine Information

| Max forming area | 1000mm*1100mm |

| Max forming depth | 130mm |

| Forming mode | Vacuum forming, press forming, mould forming, comprehensive forming |

| Forming pressure | 20t (adjustable) |

| The production efficiency | 10-15 seconds/mould |

| Dimension | 12m*2m*2.6m |

| Weight | 18T |

Product Introduction

This type of developed by combining the domestic equipment and advantages, is a set of hydraulic pneumatic servo drive for an automatic forming cutting seek.Mainly by electrical components, Japan and Germany pump, ensure the reliability of the equipment operation, and can be used for hot forming process many kinds of plastic material, it can produce PSP, PVC, PE, PP, PET, HIPES etc all kinds of packaging products, materials used in food, medical supplies, electrical components, tourism products, toys, textile, etc.The biggest advantage is forming cutting integration, reduce work link, produce the product directly, it can be collected in stacking area of work to save time, save the production base and greatly reduces the working intensity save artificially. |

Main Technical Parameters

A.Feeding part

| Feeding | Pneumatic feeding, double feeding shaft alternately |

| Feeding length | photoelectric switch controls length |

| Feeding mode | 0.75KW Turbine decelerating motor |

B.Main part

1.Omron servo system controls complete appliance chain drive, the power is 4.5kw.

2.Control mode: color touch screen,add PLC control

3.Technical parameters

Project Parameter | Quantity value | Remarks |

Process material | PS | Thickness and gram weight as request |

Total power | 150 KW | |

Total weight | 18T | |

Dimension | 12000×2000×2600 mm |

C.Heating part

Project Parameters | Quantity value | Remarks |

Heating area | 1100*2400(mm) | |

Heating mode | Ceramic radiation | Heating box can move around and be packed with asbestos |

Heating power | 90KW | |

Temperature control | Intelligent temperature controller |

D.Vacuum Forming Part

1.Forming mode: vacuum, compressive-air and die pressing integrative forming

2.Machine control mode:hydraulic single control top and bottom horizontal

3.Table stroke control:Using approach switch automatic control

4.Technical parameters

Project Parameters | Quantity value | Remarks |

Max. forming area | 1000mm×1100mm | |

Forming depth Max. | 130mm | Depth can adjust |

Forming pressure | Max. 20T | adjustable |

Oil motor power | 7.5KWX2 | Hydraulic station adopts double vane pump |

The production efficiency | 10-15 seconds/mold | |

Vacuum pump | 7.5KW | |

Vacuum tank volume | 50L |

E.Cutting Part

1.Cutting mode: hydraulic automatic control

2.Table stroke control: photoelectric switch automatic control

3.Cutting plate:High quality stainless steel

4.Technical parameters

Project Parameters | Quantity value | Remarks |

Cutting pressure | Max. 60T | |

Oil motor power | 11kw | Cutting machine adopts double vane pump |

Cutting area | 1000X1100(mm) |

F.Stacking Collection System

| Control mode | PLC automatic control |

| Stacking quantity | Automatic setup stacking placed |

| Transmission mode | Double conveyor belt deliver |

| Control mode | Pneumatic control |

| Transmission power | 0.55kw Cycloid pin shaft speed reducer |

G.Scrap Material Collection

| Control mode | Photoelectric switch control |

| Collection mode | 0.55kw Cycloid pin shaft speed reducer |

Final Products

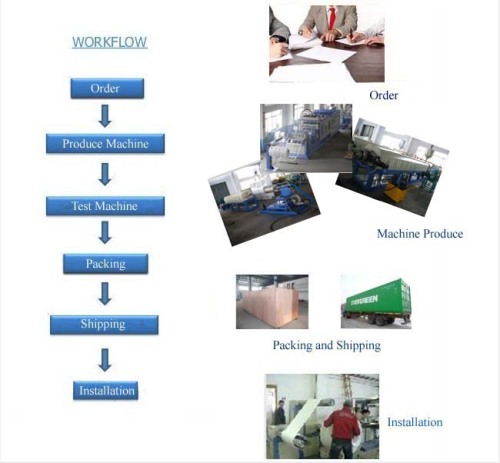

Machine Export

Our Service

Our Certification

Client Visiting

Company Information

Longkou Fushi Packing Machinery Co., Ltd

Founded in 1994,Longkou Fushi Packing Machinery Co., Ltd has developed CE certified Plastic Extrusion Machinery, Vacuum Forming Machine, Fruits Cleaning, Waxing&Grading Machine, PS/EPE foam Sheet Extrusion Line, EPE foam Net Extrusion Line, XPS Foam Board Extrusion Line, PE Cap Liner Foam Sheet Extrusion Line, PE/PS Recycling and Pelletizing Line, totally more than 20 kinds of machines, which are widely used in the fields of fruits making&processing, furniture packing, food, medical apparatus&pharmaceutical, electron, arts&crafts, construction industries, etc. |