PS Lunch Box Making Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 set per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Condition: | New |

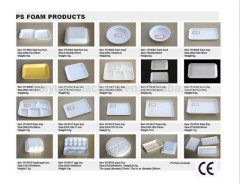

| Product Type: | PS lunch box,plate and tray |

| Place of Origin: | Shandong, China (Mainland) |

| Brand Name:: | FUSHI |

| Voltage: | 380V 50HZ |

| Certification: | CE |

| Warranty:: | One year |

| Auto: | Fully Automatic |

| Processing Type: | Vacuum Forming |

| After-sales Service Provided: | Could servise oversea |

| Production Capacity: | 50 set per year |

| Packing: | export standard packing |

| Delivery Date: | About 60days |

Product Description

HOT SELLER POLYSTYRENE PS LUNCH BOX MAKING MACHINE

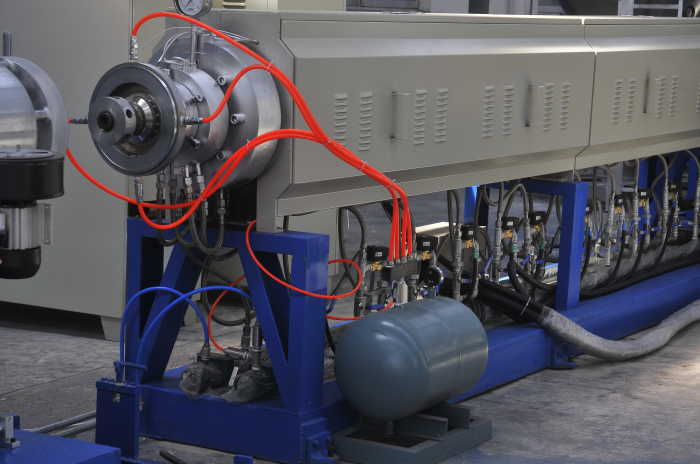

1.HIGH OUTPUT PS FOAM SHEET PLASTIC EXTRUSION LINE

MACHINE INFORMATION

High Output PS Foam Sheet Plastic Extrusion Line

| Material | PS |

| Products | Foam sheet, profiles |

| Gas injection | Butane pump |

| Density | 45-100 kg/M3 |

| Type | Tandem 65/90; 100/120; 120/150 mm |

| Screw L/D | 32:1 and 34:1 |

| Cooling | by wind or water |

| Weight | 10-18MT |

| Delivery time | 45days |

PRODUCT DESCRIPTION

| This PS foam sheet extrusion machine produce PS foam sheet, which is a kind of new-type packing with the features of shock proofing, sound insulating, heat preservation, damp proof, safety, and good plasticity. It is used widely in the packing of food, fruit, electronic product, daily necessities, hardware product, advertisement plate, etc. |

THE MAIN TECHNICAL SPECIFICATIONS:

| Model | FS-FPP75/90 | FS-FPP105/120 | FS-FPP120/150 | FS-FPP135/150 |

| Extruder | 75/90 | 105/120 | 120/150 | 135/150 |

| Foaming Rate | 20-30 | 20-30 | 20-30 | 20-30 |

| Width of product(mm) | 660 | 660-1180 | 660-1180 | 660-1180 |

| Cutting Mode | Single or double cutter | |||

| Thickness of product(mm) | 1.0-2.0 | 1.0-3.5 | 2.0-5.0 | 2.0-6.0 |

| Cooling method | Air or water cooled | |||

| Output | 60-90 | 150-220 | 250-320 | 300-350 |

| Installed Capacity(kw) | 120 | 200 | 300 | 350 |

| Dimensions(L*W*H)(mm) | 26000*4000*2800 | 30000*4100*2800 | 38000*4200*3200 | 40000*4200*3200 |

| Total Weight(T) | 10 | 12 | 18 | 20 |

MACHINE DETAILES

A.Automatic Feeding System

| Feeding style | Spiral feeding |

| The capacity of mixer (kg) | 300 |

Feeding capacity of feeder (kg/h) | 200 |

B.The First Stage Extruder

| Screw and barrel materials | 38CrMoAlA nitrogen treatment |

| Main motor style | AC-motors with frequency converters |

| Speed reducer | Extruder dedicated reducer,hard tooth surface,high torque,and low noise |

| Heater | Aluminum casted heaters, solid-state relay contactless output, intelligent temperature controller |

C.Blowing Agent Injecting System

| Type of pump | Plunger type high precision and high pressure measuring pump |

| Type of blowing agent | butane or LPG |

| Pressure gauge | 0-40(Mpa) |

D.Non-stop Hydraulic Automatic Replace Screen Changer System

| Hydraulic quickly screen changer | |

| Oil pump motor power | 3kw |

| The max pressure of oil pump | 20Mpa |

E.The Second Stage Extruder

| Screw and barrel material | 38CrMoAlA nitrogen treatment |

| Main motor style | AC-motor with frequency converters |

| Speed reducer | Extruder dedicated reducer,hard tooth surface,high torque,and low noise |

| Heater | Aluminum casted heater, solid-state relay contactless output |

| Cooling and temperature-reduction style | Circulating water cooling ,automatic bypass system. |

F.Extruder Head and Mold

Structure:Round of the extruder head,mold can adjust,head with a pressure gauge

and pressure output alarm device. The head heater ring with water cooling.

Material:High quality tool steel,heat-treated,flow channel surface roughness:Ra0.025μm

Pulling style:four-roller parallel pull, compress with air drive

Driving motor form:AC-motor, frequency conversion velocity modulation, speed reducer changes speed

G.Shaping Cooling and Cutting System

| Shaping style | shaping barrel |

| Cooling style | shaping barrel cooling with water and external wind-ring |

| Structure | shaping barrel, cutting knife and rack components |

H.Pulling System

I.Electrostatic Elimination System

Use the type of ion rod electrostatic elimination system, working volt is 7KV above,

can produce high effective and powerful ion wind, eliminate electrostatic danger effectively.

J.Winding system

FORM:Double-arm air shaft type

2.Mechanical Arm Automatic Vacuum Forming Cutting Machine

MACHINE INFORMATION

| Material | PS |

| Model | FS-YTA110-140 |

| Max. Forming Area | 1100*1400mm |

| Max. Forming Depth | 130mm |

| Forming Mode | Vacuum forming, press forming, mould forming, comprehensive forming |

| Forming Pressure | 40T (adjustable) |

| Production Efficiency | 18-22 cycles/min |

| The Control Mode | Color touch screen |

| Total Power | 200KW |

| Weight | About 28T |

PRODUCT INTRODUCTION

This machine developed by combining the domestic and foreign equipment and advantages, is a set of hydraulic pneumatic servo drive for an automatic forming cutting stacking machine. The main electrical components, such as vacuum pump,PLC,made in Japan and Germany, ensure the reliability of the equipment operation, and can be used for hot forming process many kinds of plastic material, it can produce PS kinds of packaging products, materials used in food, medical supplies, electrical components, tourism products, toys, textile, etc. The biggest advantage is forming cutting and product collection integration, reduce work link, produce the product can be stacked directly collect, this will greatly save time reduce the intensity of work and greatly saves labor. |

TECHNICAL CONFIGURATION

A.Main technical parameters

| Model | FS-YTA110-140 |

| The Chain Transmission | Omron servo control system,7.5KW |

| The Control Mode | Color touch screen |

| Total Power | 200KW |

| Power Supply | Three Phase 380V/50Hz |

| Weight | 28T |

| Main Machine Dimension | 11.6×4×2.6m |

B.Feeding Part

Unwinding Length | Photoelectric switch control |

Unwinding Mode | Turbine decelerating motors |

Feeding Method | Pneumatic feeding |

Double Feeding Shaft Alternately |

C.Heating portion

Heating Area | 1200×4400(mm) |

Heating Mode | ceramic tile radiation |

Heating Power | 160KW |

D.Vacuum Forming Part

Max. Forming Area | 1100×1400(mm) |

Forming Model | Vacuum forming, press forming, mold forming and comprehensive forming |

Forming Depth | Max 80mm |

Forming Pressure | Max 40t,adjustable |

Machine Control Method | Hydraulic control of the upper and lower mold alone |

The Production Efficiency | 3-4 seconds/mold |

Vacuum Tank | 2 pieces |

Working Table Stroke | Photoelectric switch automatic control |

Hydraulic Pump Station | With double vane pump |

E.Cutting portion

Punching pressure | Max 120T |

Punching mode | hydraulic automatic control |

Punching machine | double vane pump with oil |

Working table stroke | photoelectric switch automatic control |

Punching plate | high quality stainless steel |

Punching area | 1100×1400(mm) |

F.Stacking Collection System

Stacking method: The servo motor control the mechanical arms reciprocating motion, the mechanical arms catch the plate by vacuum sucker, it uses conveyor belt to collect the plate from both sides, and can stack 25pcs plates for single row, it is convenient to put in the carton box or bag. |

Control method | controlled by PLC |

Transmission mode | double conveyor belt transmission |

Control mode | The servo motor control |

MACHINE EXPORT

OUE CERTIFICATIONS