PS Foam Sheet Extrusion Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50set/year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | FS-FPP75/90 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | FS |

| Power: | 120KW |

| Model: | FS-FPP75-90 |

| Material: | PS |

| Thickness of sheet: | 1-3mm |

| Width of sheet: | 540/1080mm |

| Foaming rate: | 12-20 |

| Bulk weight of product: | 50-83Kg/m³ |

| Output: | 60-90kg/h |

| Rated power: | 140kw |

| Power supply: | Three phase 380v/50Hz |

| Complete weight: | About 10T |

| Production Capacity: | 50set/year |

| Packing: | Export standard packing |

| Delivery Date: | About 30-40days |

Product Description

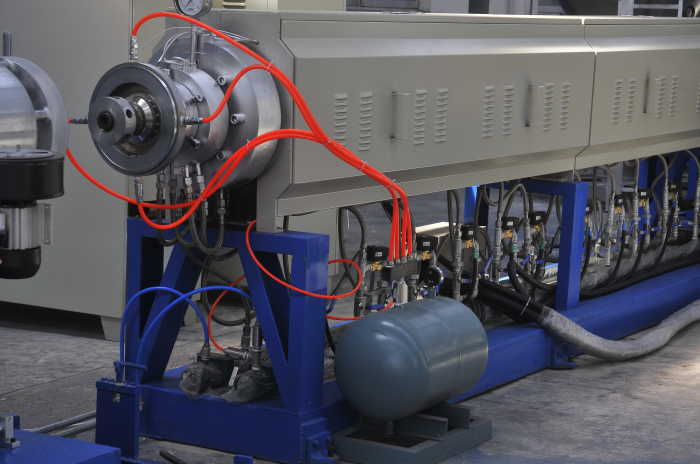

HIGH OUTPUT PS FOAM SHEET PLASTIC EXTRUSION LINE

Machine Information

High Output PS Foam Sheet Plastic Extrusion Line

| Material | PS |

| Products | Foam sheet, profiles |

| Gas injection | Butane pump |

| Density | 45-100 kg/M3 |

| Type | Tandem 65/90; 100/120; 120/150 mm |

| Screw L/D | 32:1 and 34:1 |

| Cooling | by wind or water |

| Weight | 10-18MT |

| Delivery time | 45days |

Product Description

This PS foam sheet extrusion machine produce PS foam sheet, which is a kind

of new-type packing with the features of shock proofing, sound insulating, heat preservation, damp

proof, safety, and good plasticity. It is used widely in the packing of food, fruit, electronic product,

daily necessities, hardware product, advertisement plate, etc.

THE MAIN TECHNICAL SPECIFICATIONS:

| Model | FS-FPP75/90 | FS-FPP105/120 | FS-FPP120/150 | FS-FPP135/150 |

| Extruder | 75/90 | 105/120 | 120/150 | 135/150 |

| Foaming Rate | 20-30 | 20-30 | 20-30 | 20-30 |

| Width of product(mm) | 660 | 660-1180 | 660-1180 | 660-1180 |

| Cutting Mode | Single or double cutter | |||

| Thickness of product(mm) | 1.0-2.0 | 1.0-3.5 | 2.0-5.0 | 2.0-6.0 |

| Cooling method | Air or water cooled | |||

| Output | 60-90 | 150-220 | 250-320 | 300-350 |

| Installed Capacity(kw) | 120 | 200 | 300 | 350 |

| Dimensions(L*W*H)(mm) | 26000*4000*2800 | 30000*4100*2800 | 38000*4200*3200 | 40000*4200*3200 |

| Total Weight(T) | 10 | 12 | 18 | 20 |

Machine Detailes

A.Automatic Feeding System

| Feeding style | Spiral feeding |

| The capacity of mixer (kg) | 300 |

Feeding capacity of feeder (kg/h) | 200 |

Structure:Round of the extruder head,mold can adjust,head with a pressure gauge

and pressure output alarm device. The head heater ring with water cooling.

Material:High quality tool steel,heat-treated,flow channel surface roughness:Ra0.025μm

Pulling style:four-roller parallel pull, compress with air drive

Driving motor form:AC-motor, frequency conversion velocity modulation, speed reducer changes speed

B.The First Stage Extruder

| Screw and barrel materials | 38CrMoAlA nitrogen treatment |

| Main motor style | AC-motors with frequency converters |

| Speed reducer | Extruder dedicated reducer,hard tooth surface,high torque,and low noise |

| Heater | Aluminum casted heaters, solid-state relay contactless output, intelligent temperature controller |

C.Blowing Agent Injecting System

| Type of pump | Plunger type high precision and high pressure measuring pump |

| Type of blowing agent | butane or LPG |

| Pressure gauge | 0-40(Mpa) |

D.Non-stop Hydraulic Automatic Replace Screen Changer System

| Hydraulic quickly screen changer | |

| Oil pump motor power | 3kw |

| The max pressure of oil pump | 20Mpa |

E.The Second Stage Extruder

| Screw and barrel material | 38CrMoAlA nitrogen treatment |

| Main motor style | AC-motor with frequency converters |

| Speed reducer | Extruder dedicated reducer,hard tooth surface,high torque,and low noise |

| Heater | Aluminum casted heater, solid-state relay contactless output |

| Cooling and temperature-reduction style | Circulating water cooling ,automatic bypass system. |

F.Extruder Head and Mold

G.Shaping Cooling and Cutting System

| Shaping style | shaping barrel |

| Cooling style | shaping barrel cooling with water and external wind-ring |

| Structure | shaping barrel, cutting knife and rack components |

H.Pulling System

I.Electrostatic Elimination System

Use the type of ion rod electrostatic elimination system, working volt is 7KV above,

can produce high effective and powerful ion wind, eliminate electrostatic danger effectively.

J.Winding system

Form:Double-arm air shaft type

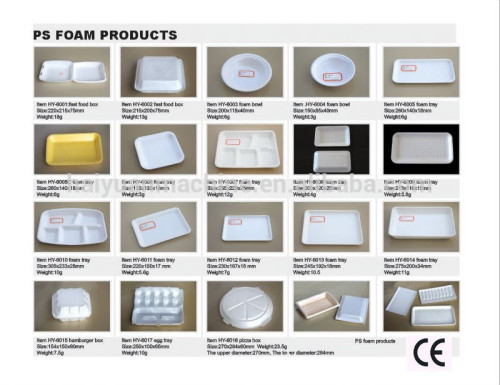

Final Products

Machine Installation

Company Information

Longkou Fushi Packing Machinery Co., Ltd

Founded in 1994,Longkou Fushi Packing Machinery Co., Ltd has developed CE certified Plastic Extrusion Machinery, Vacuum Forming Machine,

Fruits Cleaning, Waxing&Grading Machine, PS/EPE foam Sheet Extrusion Line, EPE foam Net Extrusion Line, XPS Foam Board Extrusion Line,

PE Cap Liner Foam Sheet Extrusion Line, PE/PS Recycling and Pelletizing Line, totally more than 20 kinds of machines,

which are widely used in the fields of fruits making&processing, furniture packing, food, medical apparatus&pharmaceutical,

electron, arts&crafts, construction industries, etc