CE Certification PE Foam Sheet Making Line Made In China

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100Set/Year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | FS-FPM105 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | FS |

| Power: | 110KW |

| Material: | PE |

| Product: | Foam sheet |

| Gas injection: | Butane pump |

| Density: | 20-30 kg/M3 |

| Type: | Long single |

| Screw L/D: | 55:1 |

| Cooling: | by wind or water |

| Weight: | 7.5-17MT |

| Certification: | CE |

| Delivery time: | About 45days |

| Production Capacity: | 100Set/Year |

| Packing: | Export standard packing |

| Delivery Date: | About 45days |

Product Description

CE Certification PE Foam Sheet Making Line Made In China

Product Introduction

Polyethylene foam sheet(film),also named as pearl cotton, is a kind of new-type packing material with the features of dampproof, shockproof,

sound insulation, heat preservation and good plasticity. It is an ideal substitute of traditional packing materials and used widely in the

packing of electronic product, commodity, glass, pottery, electrical household appliances, spraying, furniture, hardware product, toy, etc.

Main Parameters

Item | Unit | Parameter |

Model | FS-FPM105 | |

Applicable Material | LDPE | |

Thickness | MM | 0.3-6 |

Effective Width | MM | 1000-1800 |

Output | KG/H | 80-120 |

Maximum Roll Diameter | MM | 1600 |

Power Supply | Three Phase 380V/50HZ | |

Rated Power | KW | 110 |

External Dimension | M | 23×3.5×3 |

Weight | T | About 9 |

INTRODUCTION:

1.PE foam and related products are made from PE resin and it is expanded and formed into shapes by being heated and extruded. And it is easy to be decompounded and environment friendly.

2. Its key function is cushion protecting and warmth reserving.

3. Nowadaysitismost popularly used for modern batch production products; especially export packaging industry, including electronic industry (such as PC computer, laptop, andelectronic chips and parts, inverter, TV, air conditioner, refrigerator), furniture, glassware, garments, metal parts,etc

4. Whoever aims at modern packaging and export, he has to use PE foam for the following reasons:Packaging with air bubble film, EPS and plastic film is forbidden in many countries. Paper packaging is so expensive

5. PEhavefew varieties: Sheets for direct wrapping and to make bags; PE sheet may be coated with plastic film, craft paperand aluminum foil. It may be laminated (by electricity or LPG flame) into thick blocks. Then cut them to make different containers or frames. PE fruit net is direct for fruit and small matter's wrapping. If you add special molds, you may make different profiles for door hinges and furniture packing.

PROCESS FLOW FIAGRAM AS BELOW:

Raw material → Mixing → Input hopper →The extruder, plasticize mix → Filter and Extrude

↑ ↓

Blowing agent → Blowing agent injecting system ↓

↓

Cooling and cutting ← Shaping barrel shape ← Through extruder head and mold ←

↓

Pull and flatten → Electrostatic elimination → Winder→ Pack and Label → Warehouse entry

TECHNICAL CONFIGURATION:

A.Feeding Unit

Automatic Feeding Device

Disposal Material | Talcum Powder |

Feeding Capacity (g/min) | 2-30 |

Driving Motor (kw) | 0.75 |

| Type | Automatic feeding device |

Automatic Suction Device

Conveying Capability (kg/h) | 200 |

Motor Power (kw) | 0.75 |

Delivery Lift (m) | 4.5 |

| Type | Automatic suction device |

B.Extruder

Screw Bolt and Barrel Material | 38CrMoAlA nitrogen treatment |

Main Motor Style | Three-phase asynchronous motor with frequency converter |

Speed Reducer | Extruder dedicated reducer,hard tooth surface,high torque,and low noise |

Heater | Cast aluminum heater, solid-state relay contactless output, intelligent temperature controller control temperature |

Cooling Type | Circulating water cooling,automatic by-pass system. |

Diameter of Screw Bolt(mm) | Φ105 |

L/D ratio of Screw | 55:1 |

Max rev of Screw(rpm) | 60 |

Max Yield per Hour(kg/h) | 120 |

Number of Heating Zones | 12 |

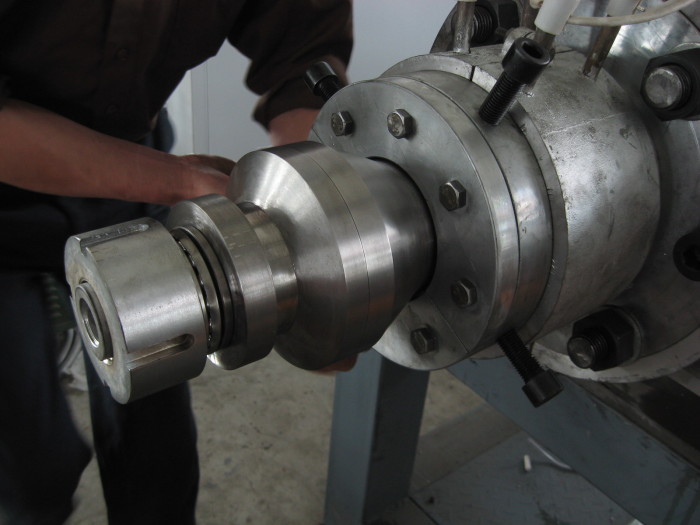

C.Non-stop Hydraulic Automatic Replace Filter System

Oil Pump Motor Power (kw) | 3 |

Oil Pump Max Pressure (Mpa) | 20 |

Filter Net Quantity(piece) | 2 |

Heating Power (kw) | 5 |

D.Extruder Head and Mold

Strcture | Round of the extruder head,mold mouth can adjust |

Material | High quality carbon forged steel,heat-treated |

Diameter of Mold Orifice | Depend on the width of production |

Zones of Temperature Control | 1 |

Accuracy of Temperature Control(℃) | ±1 |

Heating Power(kw) | 5 |

E.Foamer Injection Unit

Pump Type | High pressure measure pump |

Foamer Type | Liquefied butane |

Metering Pump Flow(L/H) | 63 |

Output Pressure(MPa) | 10-20 |

Pressure Gauge(MPa) | 0-60 |

Motor Power(kw) | 2.2 |

F.Anti-shrinkage Agents Injection Unit

Pump Type | High pressure measure pump,single-cylinder plunger type |

Anti-shrinkage Agent Type | Distilled glycerin monostearate |

Pump Flow(L/H) | 10 |

Size of Melting Pot (L) | 10 |

Pressure Gauge(MPa) | 0-60 |

Motor Power(kw) | 0.75 |

G.Air Ring and Sizer

Air Ring | Material:steel, Blowing method:Blower |

| Sizer | Material:steel ,Cooling method:wind and water,cutting method:electric circular knife. |

Blower Motor Power(w) | 550 |

Diameter of Air Ring(mm) | φ700 |

Size of Mold Drum(mm) | According to customer requirements |

Blower Motor Power of Mold Drum(w) | 550 |

H.Haul Off Machine and Expansion Frame

Carbon steel shelves quantity | 6 |

Size of mirror roller (mm) | φ400×1800 2pieces |

Size of expand roller (mm) | φ150×1800 1Piece |

Expand roller material | Aluminum |

Driving Power(kw) | 1.5 |

I.Winding Unit

Type | Dual spindle cantilever translocation type |

Coiling Weight(kg) | Max.40 |

Coiling Diameter(mm) | Max 1600 |

Length Control | Meter counter control,adjust length |

Driving Motor | Torque motor 8N.m×2set |

Revolving Driving Motor | 1.5kw gear deceleration motor |

MACHINE FOR EXPORT:

OUR CERTIFICATIONS:

COMPANY INFORMATION

Longkou Fushi Packing Machinery Co., Ltd

Founded in 1994,Longkou Fushi Packing Machinery Co., Ltd has developed CE certified Plastic Extrusion Machinery, Vacuum Forming Machine, Fruits Cleaning,

Waxing&Grading Machine, PS/EPE foam Sheet Extrusion Line, EPE foam Net Extrusion Line, XPS Foam Board Extrusion Line, PE Cap Liner Foam Sheet Extrusion Line,

PE/PS Recycling and Pelletizing Line, totally more than 20 kinds of machines, which are widely used in the fields of fruits making&processing, furniture

packing, food, medical apparatus&pharmaceutical, electron, arts&crafts, construction industries, etc.

We are one of the leading manufacturers of packing materials and related machinery. During sixteen years of development, we are highly experienced in

machinery manufacturing. With the market share expanding quickly year after year, the sales of our products are progressively increasing. The performance

of our machinery is always on the leading place compared with the same products in the market depending on quality and price.

Depending on high products quality and excellent after-sales service, our company enjoys great reputation among our customers. The products are selling

well in more than 20 provinces in China, and also exported to several countries and districts. Our excellent after-sales service could always guarantee

regular technical support to our customers.

We are pleased to welcome domestic and overseas friends to visit us and cooperate with us.

CLIENT VISSITING

DEAR FRIEND, IF YOU ARE INTEREST IN OUR COMPANY AND MACHINES, PLEASE CONNECT US AT ANY TIME, THANK YOU!

Q: Why you choose our company?

A: First, we are China Leading foam machine Manufacturer. Our company have made foam machine more than 20 years with strong experience and advanced techniques

Second, Best Quality & Best Service with Competitive price, 100% inspection Before Shipment,And we have got CE and ISO 9001 certificate

Last, we have Professional technical team, will supply 24 hours service for you Our machine have good quality, 1 year guarantee and lifetime maintenance

Q: What should we prepare except material?

A: You should prepare workshop, water tower, electric line, air compressor (if you need we can help you to buy air compressor), we can supply workshop layout drawing and equipment circuit diagram for you

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, YANTAI AIRPORT IS THE NEAREST AIRPORT from our factory, just need half hour by car,you also can fly to Qingdao Airport.

When you confirm flight No. and time please tell us then we can PICK YOU UP AT THE AIRPORT STATION

THANK YOU FOR YOUR READING, HOPE WE HAVE CHANCE TO COOPERATE WITH YOU.

THANK YOU VERY MUCH!