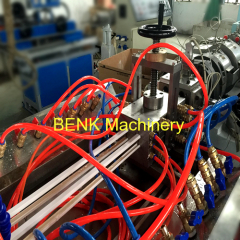

PVC Trunking Extrusion Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | kpm |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | BENK |

| screw design: | conical double screw |

| screw diameter: | SJZ65/132 |

| die design: | Four cavities |

| main motor: | 37KW SIEMENS motor |

| inverter: | 37KW ABB Inverter |

| MAX output: | 200KG/H |

| total power: | 95KW |

| instalaltion size: | 24X2X2.8M |

| machine color: | according to your idea |

| certificate: | CE ISO9001 |

| Production Capacity: | 20 sets per month |

| Packing: | suitable sea transport package |

| Delivery Date: | 45 working days after deposit money received |

Product Description

PVC Trunking Extrusion Line

PVC trunking Extrusion Line Advantage:

Thi is line is mainly used to produce PVC Trunking cable duct. it can be double out let(one trunking one cove) or four outlet (double trunking double cover) style.

Also change the dies, this line Can produce many kinds of pvc profile.

For example, PVC ceiling panel, Windows profile, Door Panel, Trunking Cable duct, Corner small profile etc.

The Machine using good brand Motor and Low voltage electric parts, Bi-metal Screw and barrel, it can making it working life much longer.

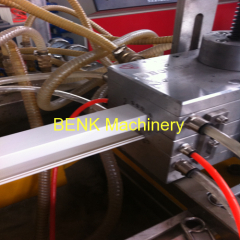

2. PVC trunking Extrusion Line Main tech parameters:

| Extruder | SJZ65/132 conical double screw extruder |

| trunking profile size | 16*16mm to 120*60mm |

| Power | 98kw |

| Output | 120-230kg/h |

| Out dimension | 24000X4000X3000mm |

| Mould | According to your design |

Except Trunking extrusion line, BENK Machinery also has other PVC profile Extrusion line with advanatage as below:

Fetching in Europe and America advanced technology and uniting with domestic condition, our company develop this production line.

This production line is mainly used to produce PVC profile, such as Ceiling, Deck, Floor, Cornice, Plank, Windows, Door frame and board and etc.

Feature:

1. Conical twin-screw extruder, suitable for processing PVC powder and WPC raw materials.

2. Changing the moulds to produce many kinds of different PVC profiles.

3. Auxiliary machine: Mixing unit, Mould, Vacuum calibration table, Haul-off machine, Cutter and Stacker.

PVC profile extrusion line technical parameters:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||