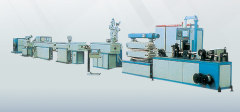

PE Pipe Extrusion Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | kpm |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | BENK |

| pipe range: | 16-2000mm |

| main extruder: | single screw extruder |

| capcaity: | 120-1500KG |

| Main motor: | XIMO |

| electric parts: | SIEMENS, Shneider, OMRON |

| Certificate: | CE ISO9001 |

| suitable material: | PE/PP |

| pipe function: | GAS, water supply, pressure pipe etc. |

| installation size: | 50x4x4M |

| machine color: | according to your idea |

| Production Capacity: | 20 sets per month |

| Packing: | suitable sea transport package |

| Delivery Date: | 60 working days after receive deposit money |

Product Description

PE Pipe Extrusion Line

1. PE Pipe Extrusion Line introduction:

High speed PE pipe extrusion line is an new product in this filed, it can produce PE pipe double speed than normal line, using SJ65/38 high speed single screw extruder, combined with vacuum forming tank, spray cooling tank, haul-off, cutter and high speed double disc winder making it working high efficency and stable.

the production line is ZHANGJIAGANG CITY BENK MACHINERY CO., LTD. developed a new type of pipe production line for PE , pp and other polyolefin pipe with high extrusion speed , all models with advanced PLC/PCC modular intelligent control system , in order to realize the whole production line automation and real-time data recording and closed-loop control , the production line has some high yield , wide adaptation of raw materials , suatained and stable production of high quality productions such as columns a bit .

2. PE Pipe Extrusion Line technological flow chart:

drying feeding--main extruder andmark color extruder---head mould---vacuum molding---thickness finder(can be choosen by self)----vacuum calibration tank---spray cooling tank---printer--haul-offs---cutter---stacker

3. PE Pipe Extrusion Line technical parameters(high speed):

| Model | Pipe spec(mm) | extruder | Max.output (kg/h) | Total power(kw) |

| KPM63-PE | Φ20-Φ63 | SJ65/38 | 250-300 | 75/90 |

| KPM110-PE | Φ63-Φ110 | SJ65/38 | 250-300 | 90 |

| KPM250-PE | Φ75-Φ250 | SJ75/38 | 500-550 | 185 |

| KPM450-PE | Φ160-Φ450 | SJ90/38 | 700-750 | 250 |

| KPM630-PE | Φ315-Φ630 | SJ120/38 | 900-1100 | 280 |

| KPM800-PE | Φ400-Φ800 | SJ150/35 | 1000-1200 | 315 |

| KPM1000-PE | Φ630-Φ1000 | SJ150/38 | 1000-1200 | 315 |

| KPM1200-PE | Φ800-Φ1200 | SJ120/33 & SJ90/38 | 1500-1700 | 280/220 |