High Speed Extrusion Line for PE/PP Double Wall Corrugated Pipe

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100 lines per year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | kpm |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | BENK |

| pipe range: | 90-1500mm |

| main extruder: | single screw extruder |

| capcaity: | MAX 350-1500KG/H |

| Main motor: | XIMO |

| electric parts: | SIEMENS, Shneider, OMRON |

| Certificate: | CE ISO9001 |

| suitable material: | PE/PP |

| pipe function: | GAS, water supply, pressure pipe etc. |

| installation size: | 20x4x4M |

| machine color: | according to your idea |

| Production Capacity: | 100 lines per year |

| Packing: | suitable sea transport package |

| Delivery Date: | 60 working days after receive deposit money |

Product Description

High Speed Extrusion Line for PE/PP Double Wall Corrugated Pipe

Authentic German Technology

1. All-new mould blocks cooling method. The mould blocks are cooled continuously by "pressure cooling" water circulating in sealed channels to achieve higher cooling efficiency and higher production speed, which strongly guarantee lower pipe production cost.

2. Through FEA profile design technology and lots of practical application feedbacks from our customers, our professional engineering design team can ensure optimization of pipe profile data adapted for various materials and purposes. Lower cost of pipe material for you.

3. Highly compatibl etechnical solution of mould blocks. The mould blocks can be compatible between different models of production lines in order to make the production more flexible with lower maintenance cost.

4. All-new design of "none platform" for corrugator. Need not to adjust the height of corrugator when change the moulds for different sizes. Operations become easier and more efficient.

5. Innovative rapid assembly of mould blocks inclasp style simplifies the operation of changing mould blocks and greatlyshortens the down time.

typical structure of

High Speed Extrusion Line for PE/PP Double Wall Corrugated Pipe

| Model | KPM-250 | KPM-500H | KPM-800H | KPM-1500H |

| Diameter of pipe (DN/ID) | 90mm-250mm | 200mm-500mm | 200mm-800mm | 800mm-1500mm |

Finial products:

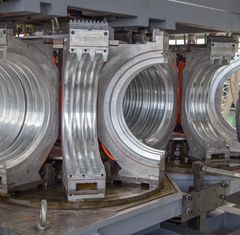

DETAILED IMAGES

Forming dies Gas water pressure control

Electric cabinet Gearbox of extruder

SIEMENS PLC control Servo motor control forming machine

EXHIBITION SHOW

CERTIFICATIONS

PACKING: WOOD PALLET COVERED BY PLASTIC FILM

AFTER-SALE SERVICE

1.Technical documents:All the symbols on the equipments should be in English. Seller is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on time.

2.Arrangement for inspection, installation and testing work: BENK will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory. Engineer will give free training lessons to labors in buyer's factory.

3.BENK will provide long-term technical guide.