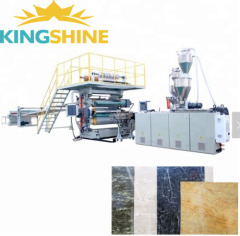

PVC celling panel extrusion line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300 LINES PER YEAR |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | KPM-C600 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | BENK |

| panle wide: | 200-600mm |

| extruder: | SJZ51/105 or SJZ65/132 |

| capacity: | 80-120KG/h 150-180KG/H |

| total power: | 53KW |

| instalaltion size: | 16X2X2.8M |

| Certificate: | CE ISO9001 |

| machine color: | according to your requirements |

| Production Capacity: | 300 LINES PER YEAR |

| Packing: | suitable sea transport package |

| Delivery Date: | 35 working days after deposit money received |

Product Description

PVC celling panel extrusion line

1, machine introduction:

The PVC celling panel extrusion line uses PVC or UPVC as raw material to produce various kinds of profiles for roof and decoration profiles.

The extruder haul-off adopts frequency inverter for speed control, the whole line can realize stepless speed regulation;

*The vacuum calibration stand uses water cycling type closed vacuum system, equipped with centralized water supply and quick-change coupler, realize fast and easy change the different models of calibration mould;

The haul-off adopts belt type, guarantees stable production and the profile do not get deformed; the automatic lamination device guarantees are smooth surface of profiles;

The cutting machine is synchronous system, guarantees the cutting section is smooth and no split after cutting.

The complete production is energy saving, stable performance, high efficiency. The profiles from this line have advantages of good looking, strong to bear compression, good light stability and thermo stability, age-resistance, etc.

2, reference pics:

thickness checking red light

extrusion die:

haul-off

cutter

3, PVC celling panel extrusion line main technical parameters:

| extruder | SJZ51/105 | SJZ65/132 |

| main motor | 22KW | 37KW |

| panel MAX width | 300mm | 600mm |

| potput | 120kg | 230kg |

| instalaltion size | 16X2X2.6m | 16X2X2.6m |

| installation power | 45KW | 61KW |

PVC celling panel extrusion line machine list:

Specification of Equipment List | |||

NAME | Quantity | Description | Remarks |

Automatic feeding machine | Set | Spiral loader | |

Feeding hopper | 1 | With twin screw to feed evenly | |

Extruder SJSZ-51/105 or 65/132 | 1 | 22/37 KW | |

Moulds | 1 | Moulds shape can be designed | |

Calibration Table | 1 | Vacuum pump 5KW,3KW | |

Laminator films | 1 | Surface treatmen | on line |

Haul off machine | 1 | For driving the products | |

Cutting | 1 | Cut | |

4, draft installation drawing

Interest it? pls do not hesitate to contact us for more inform.

Thanks!