H beam steel prefabricated houses

| Min. Order: | 25 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000/year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Service |

Product Detail

| Model No.: | SW-12 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Senwang |

| Brand: | Senwang |

| Color: | Red,green,off-white and ects |

| size: | According to the customer |

| Roof&wall materia: | galvanized steel sheet ,EPS,Glass wool,rock wool and pu sandwich panel |

| Mail steel frame: | Steel frame |

| Drawing design soft: | utoCAD,PKPM,MTS,3D3S, Tarch, Tekla |

| installation: | assigning our engineer on site |

| used: | workshop plant/warehouse/hangar/poutry shed/office and ect |

| Application: | workshop |

| Type: | Light workshop |

| Production Capacity: | 5000/year |

| Packing: | according to customer |

| Delivery Date: | 30 days after got the payment |

Product Description

H beam steel prefabricated houses

Materials:

1.Main structure: welding H steel or hot rolled H steel,all bolts

connection straight cross-section or variable cross-section.

2.Purlin: C section channel or Z section channel

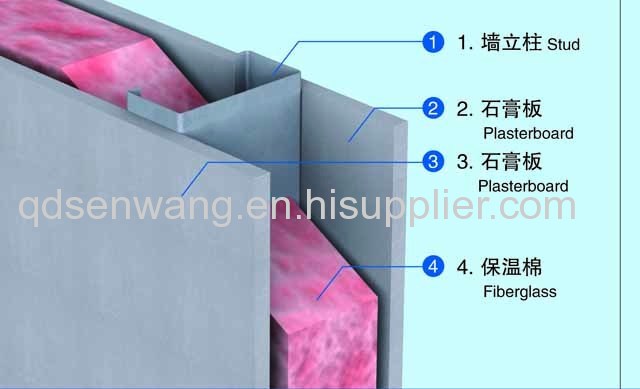

3.Roof cladding: corrugated steel sheet or sandwich panel with fiber glass wool, EPS, rock wool, PU

4.Wall cladding: corrugated steel sheet or sandwich panel with fiber glass wool, EPS, rock wool, PU

5.Column barcing and transverse brace: angle steel or H section steel or steel pipe

6.Knee brace: angle steel

7.Roof ridge: corrugated steel sheet

8.Wrapping cover: color steel sheet

9.Roof gutter: color steel sheet

10.Rainspout: PVC pipe

11.Design : According to your drawings or some details needed.

12.Fabrication : Strictly fabricate every member based on the drawings confirmed.

13.Transportation : Good relationship with CSCL,OOCL,MSC,Maersk matine lines and etc.

14.Installation: Complete instructions for installation, or technical support by

assigning our engineer on site.

15.Bearing: The steel structure makes the house resisting heavy wind by

100km/h and 7grade earthquake.

16.Protection: Color steel sandwich panel has a good fire proof and heat insulation

performance for the characteristic of the color steel sheet

Factory building sandwich panel for the wall and the roof

Equipment showing

Product Description

Thinckness 50mm,75mm,100mm,120mm,150mm,180mm, 200mm,the standard width is 985mm,the length can cut as customer's requirment.

* Thinckness 50mm,75mm,100mm,120mm,150mm,180mm, 200mm,the standard width is 985mm,the length can cut as customer's requirment.

* PU color steel cold storage panel systems (Pu cold Panel)

1) Advantage:

* Energy conservation, environmental protection, economical, heat

insulation, good structure, easy-doing construction, low installation cost

2) Feature:

* Good quality color steel, filled with high-density PU (The density can reach 42kg/m3)

3) Application field:

* Medical research, constant temperature in factory, refrigerator and some other places needing special temperature

Packaging & Shipping

Company Information

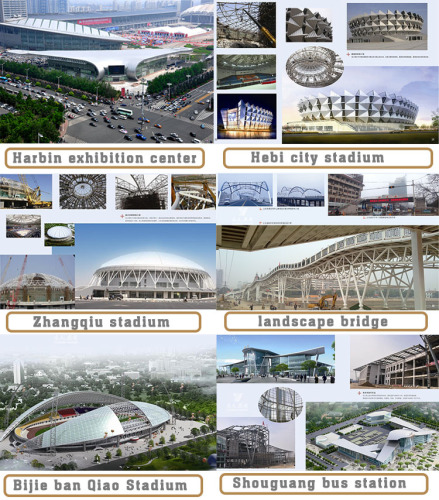

we are big group factory and have more than 25 years experience of steel structure workshope project The first design&Engineering Service,Excellent product and perfect Has won the praise of customers and want to cooperation with more and more friends and customer add us team .

Our service

1. Professional design and engineering team

Full solution for house design. We could make the design for whole house as per your requirement.

2. Procurement and Manufacture for all material for prefabricated building

We have a professional procurement team to make sure all the materials are with good quality. And our factory operation under ISO standard, to make sure the fabrication works with high technology.

3. Site management & Installation supervision

We could send our engineers to help for the installation supervision, you just need to prepare a team which know normal construction works will be OK.

FAQ

1. Speed of construction and camp installation Allows for the building and the site work to be completed simultaneously, reducing the overall completion schedule, all the Main Structures will be connect with bolts, no welding works. All the wall and roof structure, flooring will be fixed by Self-tapping Screw or nails, normal Carpenter team could make a good job!

2. Economical Solution, compare to concrete building, prefabricated building will be much more Economical

3. Ability to service remote locations Assembling a work camp close to the work site reduces travel time which reduces cost.

4. Long time span Well-built modular worker camps can last for 10, 15 or 20 years or more.

5.Safe and stable, Earthquake resistance: Grade 7, Wind resistance: Grade 11(wind speed≤ 120km/h)

connect information