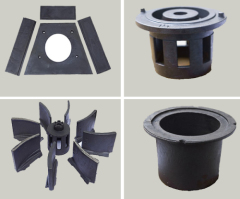

Blast Wheel (German Cooperation Technical)

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 500 sets per year. |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | H400 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | KNNJOO |

| Certification: | CE BV TUV ISO9001 SGS |

| Color: | Customers' requirement |

| Blast wheel: | Low noise level |

| Separator efficiency: | 99.99% |

| Application: | Electronic Industry |

| Clean type: | Clean-in place |

| Cleanliness: | Sa2.5 |

| Leading Market: | Global |

| Cleaning process: | Abrasive |

| After-sales service provided: | Engineers avaliable to service machinery overseas. |

| Production Capacity: | 500 sets per year. |

| Packing: | Standard Package for Sea Shipment. |

| Delivery Date: | Date of payment within 10 days of delivery |

Product Description

Describtion

The KNNJOO technology center products the H400,H900 series high-power direct coupling shot blasting machine is ideal for all heavy-duty applications and casting.The blasting has high flexibility, compactlly,can rotation in both directions.

This blast wheel is large capacity blast wheel,Asian's only patent,it has high energy efficiency.Rugged designed,make it easy to maintence,Special high wear-resistant cast alloy lining blast wheels ensure minimum wear and maximum service life.

Through ensure flexibility,large capacity and high efficiency to improve profitability.

Our company use the newest technology in solutions of blast wheel,to meet the growing demand for surface treatment.Universal blasting wheel can ensure the higher cleaning performance and the highest energy efficiency,fulfill or even exceed customers expectations.

Universal blast wheels' performance under harsh application conditions,especially amply documented in using of heavy machine .Shot blasting clean effect is remarkable,and it's easy to maintenance(Long maintenance cycle, cost savings, easy access to the required maintenance time is short).

Shot blasting wheel is designed to meet a number of requirements, including a variety of designs, sizes and power ranges.

• Design: Direct drive transmission

• Dimensions: H400, H900

• Power range: 7.5 to 120 kilowatts

• Different blade length (enveloping circle diameter): 380 mm (340 mm / 410 mm); 500 mm (430 mm)

• blade width: 80,105 mm

• Frequency: 50/60 Hz or drive

Options

• Wear-resistant material or a cemented carbide

• Directional electric or pneumatic sleeve set

• Tensioning device

• Shot housing rotatably (shot blasting stream positioned to meet the needs of a specific workpiece)

Shot reversible rotation, high flexibility

Product Features

• Compact design - Direct Connect technology, the only of Asian.

• Abrasive distribution (projection angle, intensity peak) strength can be improved in order to ensure maximum cleaning efficiency.

• Projectile velocity is almost infinitely adjustable to meet all customer requirements.

• Shot streaming settings easy operation, high precision, to ensure the best Shot Blasting efficiency, and to minimize the wear liner and machines.

• Lower blast wheel hub height, angle can be adjusted freely to adjust the abrasive flow.

• Shot blasting can reverse the direction of rotation by remote control, without any manual intervention, and can take many different parts.

OUR COMPANY

Our company is a set research, development, production, operating as one of the industry entity. Engage shot blasting machine industry more than forty years, has a strong research and development, advanced production technology, perfect detection means, scientific management system. As a professional manufacturer of shot blasting machines, industry, technology, quality, and level of automation in the domestic industry with the advanced level. The company's main products are bar shot blasting machines, road shot blasting machine, hook type shot blasting machine, crawler shot blasting machine, through shot blasting machine and so on.

Please contact us for more information.