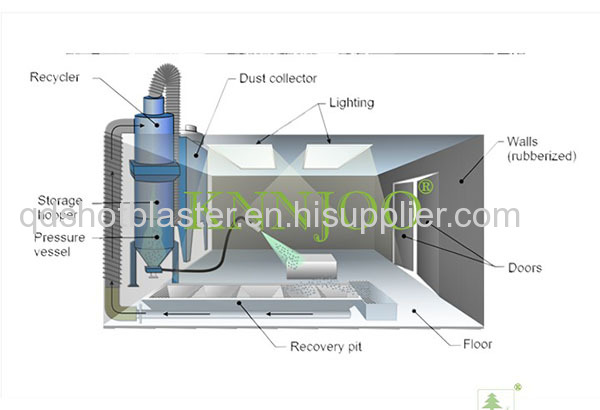

International Certification Sand Blasting Chamber

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 30 Sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | QGL |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | KNNJOO |

| Certification: | CE BV TUV ISO9001 SGS |

| Color: | Customers' requirement |

| Application: | Electronic Industry |

| Clean type: | Clean-in place |

| Separator efficiency: | 99.99% |

| Function: | Cleaning machine |

| Cleaning process: | Abrasive |

| Blast wheel: | Low noise level |

| Condition: | New |

| After-sales service provided: | Engineers avaliable to service machinery overseas. |

| Production Capacity: | 30 Sets per year |

| Packing: | Standard Package for Sea Shipment. |

| Delivery Date: | Date of payment within 60 days of delivery |

Product Description

Qingdao KNNJOO Machine INC. offers a complete range of robotic solutions, in the robot control and the shot blasting workpiece handling robot incorporated into the process, the pre-and post-processing has a wealth of experience.

Robot gripper system can be used for shot blasting and blasting operations. Robot gripper and the workpiece holder in combination to grab and move the blasting nozzle or the front part. This means that each robot gripper system always includes an automatic workpiece loading / unloading system. To prevent leakage of pellets, flexible and effective seal is essential. Qingdao Chun nine developed for the robot gripper using the most flexible seals, and obtained a patent. The robot gripper ring has been successfully applied.

Senior Internal blast cleaning machine -NBPW

Knnjoo advanced internal blast cleaning machine (NBPW) is the industry's first, to improve efficiency and repeatability while improving quality and reduce processing time.

Application:

- Mainly used to clean the inside of the hole and the water jacket of the cylinder head, crankcase, the engine case and other similar complex castings.

The main advantages:

• Thoroughly clean the inner surface of the opening

• Full process control system to achieve repeatability of process parameters • Traceability

• Tools can be reversed, increase flexibility and reduce the unit cost of the parts

• Easy maintenance, lower operating costs, improve uptime and utilization

• global support system to ensure optimum performance and uptime

• Knnjoo experience and reliable and stable to minimize your risk

• quality parts can provide protection for safety and process uptime

About us

Our company has decades of experience in manufacturing shot blasting machine, there are dozens of experienced engineers and many employees, which received many certificates in the field, our company's products are favored by many customers.

Our company has a global marketing systemand and products are exported to 49 countries of the world .

Our company has 20 professional engineers and many staffs in our Qingdao Foundry Machine Co.,Ltd.

Our company has 50 years of experience in the manufacture of shot blasting machines aspects.