Continuous Flow Shot Blasting Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 30 Sets per year |

| Place of Origin: | Shandong |

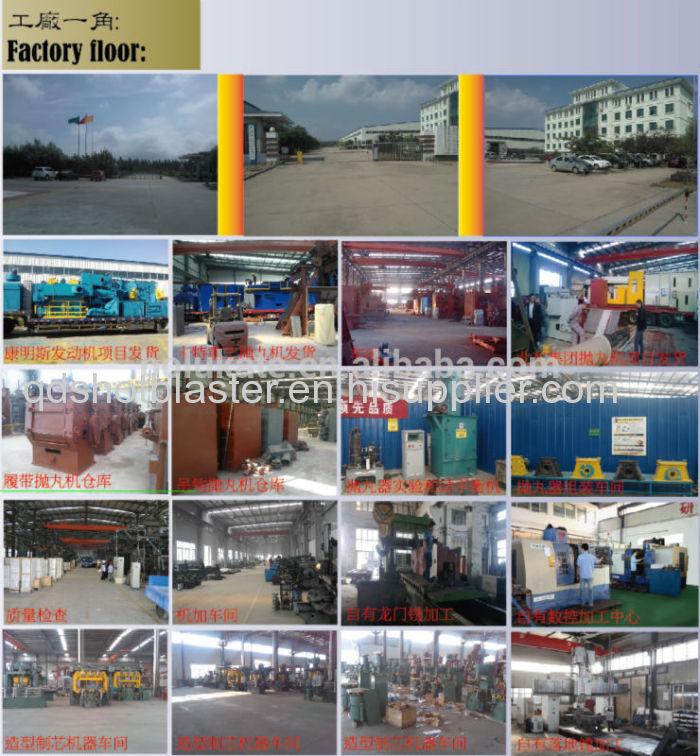

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | CT |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | KNNJOO |

| Certification: | CE BV TUV ISO9001 SGS |

| After-sales service provided: | Engineers avaliable to service machinery overseas. |

| Application: | Electronic Industry |

| Clean type: | Clean-in place |

| Separator efficiency: | 99.99% |

| Blast wheel: | Low noise level |

| Cleaning process: | Abrasive |

| Condition: | New |

| Function: | Cleaning machine |

| Leading Market: | Global |

| Production Capacity: | 30 Sets per year |

| Packing: | Standard Package for Sea Shipment. |

| Delivery Date: | Date of payment within 50 days of delivery |

Product Description

Describtion

Automated manufacturing processes require highly flexible production systems to meet changing production requirements. Flexible system that can quickly adapt to the production speed, batch size, change finishing processing technology and market demand.

Feed through the cleaning process has many obvious advantages, shot blasting to ensure efficient and cost-effective. Continuous shot-blasting machine will not only help automate the production process, but also improve the working environment.

KNNJOO machine company introduction of German technology to produce a continuous track applied by shot blasting machine aerospace, steel, automotive, forging and other industries, and continuously optimized based on the original, so that more mature and advanced technology to give European and American customers.

Application

• Casting cleaning and coring.

• Castings and forgings rust.

• Mixed or single production line.

• Multiple Parts Mixed Cleanup.

• Regardless of fluctuations in productivity, can always maintain efficient blast cleaning performance.

Advatage

• From modeling to fine soil preparation fully automated production lines.

• Production processes clear arrangements, improved product consistency to be increased dramatically.

• Without intermediate stacking area, reducing the transmission distance.

• As the entire blasting process can be integrated into an automated production line, operating costs are reduced.

• Small footprint.

• Dangerous artifacts be treated almost without any manual handling, an improved working environment and eliminate operator.

Shot Blasting automatic, continuous, clean.

KNNJOOSteel track shot blasting machine can be tilted continuously rotating casting cleanup.Ensures gentle workpiece flip. Trundle bed rotational frequency and quantity of shot blasting the pellets according to the parts flow and volume are controlled by pre-programmed parameters.Even in the case of irregular flow of parts, we can ensure the best shot blasting effect and minimal wear. Efficient Pill stream flow from the upper part can be completely clean all surfaces and interior areas.

| CT 16-650 | CT 20-650 | |

| Max.Diagonal line size(mm) | 600 | 600 |

| Continous processing capacity(T/h) | 5-12 | 10-25 |

| Max.weight of workpiece | 65 | 65 |

| Blast wheel quantity | 2 | 4 |

| Blast wheel power(Kw) | 15-45 | 15-45 |

.jpg)

.jpg)