Automatic Intelligent Control Manipulator Shot Blasting Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100 sets per year. |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | PE |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | KNNJOO |

| Certification: | CE BV TUV ISO9001 SGS |

| After-sales service provided: | Engineers avaliable to service machinery overseas. |

| Application: | Electronic Industry |

| Color: | Customers' requirement |

| Condition: | New |

| Cleanliness: | Sa2.5 |

| Separator efficiency: | 99.99% |

| Place of origin: | Shandong,China(Mainland) |

| Clean type: | Clean-in place |

| Cleaning process: | Abrasive |

| Production Capacity: | 100 sets per year. |

| Packing: | Standard Package for Sea Shipment. |

| Delivery Date: | Date of payment within 30 days of delivery |

Product Description

Production Describtion

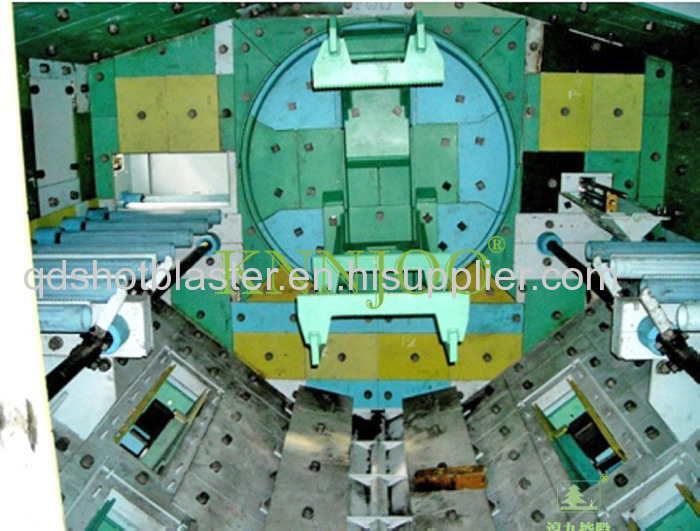

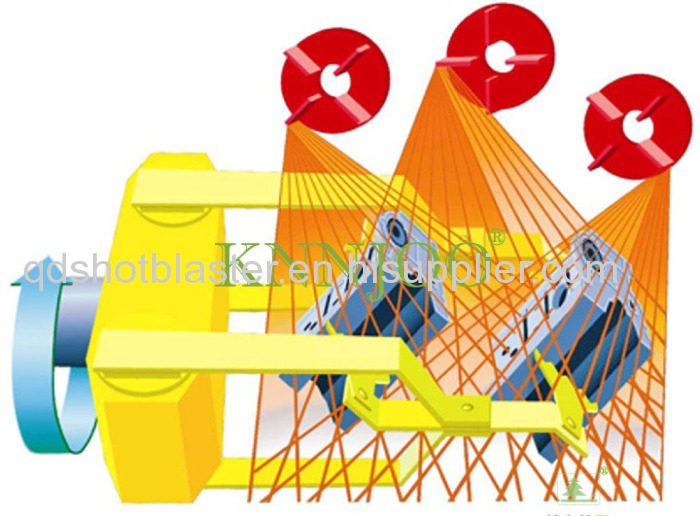

Robot shot blasting system suitable for large series casting or forging Powertrain machining shot blasting and cleaning. Today, the system has become the foundry industry, and an integral part of the forging industry. Manipulator shot blast cleaning systems meet the highest production demands, and its excellent blasting treatment effect is well known: Even within the diffficult workpiece surface can be deal with clean-up in place, without any residual abrasive. Wheelabrator range of products and a unique layout features (load / unload) to efficiently solve various production tasks possible. Capable of manufacturing processes and materials processing flow perfectly together to achieve a complete installation to avoid risk. Process automation to improve production efficiency and economic benefits. DS series shot blasting machine containing one or more horizontal rotary robot. DV series shot blasting machine having a plurality of vertical rotary robot.

Mechanical circulatory system includes a workpiece transport device, robot gripper rotating equipments rotating equipments and the exhaust pill.

Workpiece motorized rollers provided with a position detecting device and position control equipments. Position control equipments force the workpiece and the motorized roller slippage, by the position detection means detects the workpiece stop motorized roller.

Feeding center in the workpiece positioning device determines the lateral center position of the robot claw clip. Stripper centering equipments determines the lateral center position of the workpiece at the discharge of motorized rollers. In order to successfully enter the work rotating device row pill.

Working position detecting cylinder to force the workpiece and the motorized roller slippage, the signal generated by the collision, determine the workpiece in the longitudinal center position of the robot claw clip.

Feeder on the workpiece through the rise - advance - decline - back action. Motorized roller from feeding the workpiece to the mechanical men jaws.

Unloader workpiece by advancing - rise - back - drop operation. Motorized roller to discharge the workpiece from the mechanical claw hands will clip.

Loading and unloading at the place were two instances pneumatic sealing door, and the blast area is isolated.

Robot gripper rotating device, controlled by the drive two speed determined by the rotation angle of the rotary encoder. It can be stopped at any angle.

Discharge rotary device by the inverter control pill two speeds.

DS / DV type robot shot blasting machine is flexible and efficient, capable of handling different shapes and sizes of components, there is no need to replace equipment. For high processing capacity and superior cleaning efficiency of the blasting system performance is very outstanding.

Applitation

• Gearbox,cylinder block, cylinder head, crankshaft and intake manifold ex.and cast iron and aluminum parts series'shot blasting,descaling and shot strength.

Six kinds of basic models and the flexibility provided by the modular design to meet the output, and covers the various requirements of material handling layout.Robot shot blasting machine can be used in conjunction with sandblasting room, and is suitable for automatic cleanup line.

The shot blasting machine is equipped with rotating support shaft or flexible mechanical clamps, it is able to crawl and transferred to the workpiece shot blasting equipment.

Advantage

Fully automatic operation, including loading and unloading of the workpiece.

Automatically different shapes and sizes of shot blasting castings, without replacing equipment.

Improve efficient in the use of pellets thereby minimizing the degree of wear of mechanical parts.

Programmable robot movement (rotation, swing and stop), targeted to the surface and the interior passageway to clean up.

Removing the pellets within the inner shot blasting machine cycle time. Workpiece after cleaning without residue pellets.

Good processing capability, can process up to 40 tons per hour of casting, casting each piece can weigh up to 700 kilograms.

Loading equipment or industrial robots put the unclear workpieces or the robot placed to the support shaft and fixed.Spring-loaded clamp mechanism for holding the grip.Shot Blasting parameters fully automated blasting systems can be equipped with sensors to identify and control specific parts of the workpiece(Shot clean-up time, the number of pellets, the projected speed, movement of the workpiece during Shot Blasting, shot blasting the role of the number of pellets removed time).The correct placement of the workpiece to ensure continuous contact with the complete workpiece shot blasting stream, using pellets of the best efficiency levels and wear of mechanical parts is minimized.

Our service

Quality and After-sale Assurance:

1. Supplier promise the name, model, specification and quantity comply with technical protocol,

assuring the machine is new equipment with qualified material manufactured through perfect technology.

There are no defects in design, material and technologies, which is suitable for propose of demander,

and meets the standard of national industry. The quality is stable and reliable.

2. Equipment warranty and After-sale Assurance Engineers available to service machinery overseas

( except force majeure, inappropriate operation and the quick-wear parts wears).

3. The equipment will pass the installment and test before delivery, after the quality is qualified.