Ecoweb Geocell for Slope Protection

| Min. Order: | 1000 Square Meter |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | T/T |

| Supply Ability: | ONE 40' container is around 15 days |

| Place of Origin: | Anhui |

Company Profile

| Location: | Chaohu, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | Ecoweb |

| Color: | sand/green/black |

| Production Capacity: | ONE 40' container is around 15 days |

| Packing: | Plastic pallet or as customer's request |

| Delivery Date: | It depends on |

Product Description

1. Product Introduction:

Material: HDPE

Place of origin: China

Cell Depth: 50-300mm

Weld Spacing: 260-1000mm

Color: sand, green, black

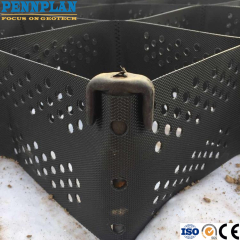

Type: Textured & perforated

Thickness: 1.5mm

Seam Peel Strength: >16KN/m

Packing: pallet or as customers' requests

2. Product Technical:

1. High Weld Strength: >16kN/m for peel strength, >30kN/m for split strength

2. High Tensile Strength: >30MPa

3. High Elongation: >900% (TD) >480%(MD)

4. OIT: >200mins

5. Wall Depth Maximum 300mm

6. Strip Length Maximum 8m

3. Application:

Load Support

Retaining Wall

Slope Protection

Channel Protection

4. Ecoweb Advantage:

1. Ecoweb is stable and flexible with various types including:

· Strip Height: 25mm, 50mm, 75mm, 100mm, 125mm, 150mm, 200mm, 250mm, 300mm.

· Weld Spacing: 260mm - 1000mm

· Strip Length: Maximum 8m long.

2. Production Capacity:

· With two automatic welding lines, our production capacity is 2000-2500 m2 per day.

3. High Performance:

· Tensile Strength at Break: >25 kN/m ASTM D6693

· Seam Peel Strength: >16 kN/m USACE GL-86-19

· Elongation at Break: >900 % ASTM D6693

· Oxidative Induction Time: >150 min ASTM D3895

5. About us:

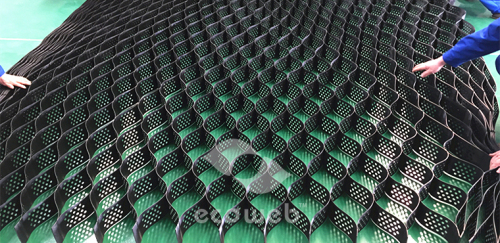

Ecoweb Geocell is widely used in construction for erosion control, soil stabilization on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth retention. It is made with ultrasonically welded high-density polyethylene (HDPE) strips and expanded on-site to form a honeycomb-like structure, and filled with sand, soil, rock, gravel or concrete.