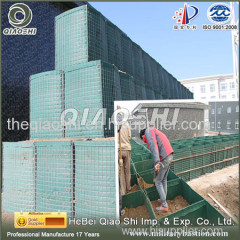

JOESCO military camp base hesco perimeter wall

| Min. Order: | 10 Bag/Bags |

|---|---|

| Payment Terms: | D/P, T/T |

| Supply Ability: | 1000000 set |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | 3 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Others |

| Type: | Welded |

| Material: | Others |

| Brand Name: | JOESCO |

| Mesh Size: | 75X75MM |

| army barrier: | joesco army hesco |

| Hesco Geotextile Color: | beige and green |

| Product Name: | Detachable type hesco |

| Hesco Usage: | military and civil application |

| Hesco Certification: | Patent and ISO |

| Hesco Hole shape: | Square Hole |

| Hesco Aperture size: | 75x75 mm |

| Hesco wire diameter: | 4-5mm |

| Hesco geotextile: | heavy duty non-woven polypropylene |

| Brand: | JOESCO HESCO |

| Production Capacity: | 1000000 set |

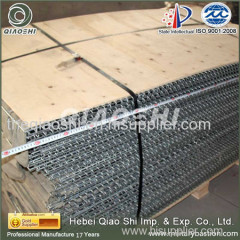

| Packing: | pallet |

| Delivery Date: | 10 days deposit |

Product Description

If need, please feel free email to salesf(at)theqiaoshi.com

Regards,Richeal

Skype:richeal

Use of JOESCO bastion:

Wide,diverse and ranges from civil engineering with soil retaining walls, flood prevention and the prevention of coastal erosion. Military uses are considerably more diverse. JOESCO bastion units have been used in the construction ofAmmo compounds;.Noise abatement barriers;Sentry towers;Guard posts, both improvised and in kit form;Vehicle barriers;Entry control points;Blast mitigation walls;Cover from view;Protection for aircraft revetments;Protection of adjacent occupants from the accidental discharge of aircraft weapons;Protection of living accommodations;Provision of bomb shelters;Asset protection.

The list is not exhaustive. The use that which JOESCO bastion units can be put to is only limited by the user's imagination and a few construction engineering considerations

Fill material requirements:

One of the main advantages of JOESCO bastion units is its ability to be filled with almost any fill material. Only large rocks and clumps of earth should not be used.

For hastily required defensive positions almost any locally won fill material will suffice. The only material that should be avoided is that which contains large lumps that may create voids or damage the cells during the filling operation. Large pieces of material may also become dangerous pieces of shrapnel. Avoid organic material if possible but it is realized that in some tactical situations this may not be possible as it may be the only material available.

The users of a particular fill material is going to dependent on one or more of the following: the type of material available;the length of time the structure is likely to be employed;the perceived threat;the handling equipment available

If during the planning of the structure it is believed that it is to be in place for a time exceeding 6 months it is essential that a material with good construction characteristics is chosen. Well graded sand with low tines content, or crushed rock is ideal for long term structures.

Construction Techniques:

There are a variety of equipment types that can be utilized to fill JOESCO bastion units. Like: wheeled and tracked excavators filled with either standard buckets or clam-shell grabs;Tipper truck/dump trucks fitted with lorry loader grab attachments;Concrete skips lifted by cranes, and skid steer loaders. The simplest and easiest to use is a front end-loading shovel. Particularly when the structure is below 3.5 meters(11')high.Front end loading shovel size should be selected to match the size of bastion cell being filled. The front bucket of a backhoe loader is suitable for all cells up to QS1 in size.

Many factors will effect the time and numbers of operatives that it takes to construct any given structure, but the more common ones are: Availability of resources and manpower;Haul distance from stockpile for the fill material

.Accessibility and ground conditions;Type of JOESCO bastion unit being used;Experience of the operatives with the system and the structure being built

The key to working out the quantity of manpower required:Ascertain time available for the construction;Calculate the construction time with 4 men and loading equipment.This is your basic construction figure, if you cannot achieve completion within the given time frame then an increase in manpower and equipment is required.

For basic linear construction of 2 JOESCO bastion QS1 unit of 10.6m length, 10 cells, allow 20 minutes using one loading shovel and 4 men. This includes unpacking from a pallet, bouncing the cells out and filling. This is as good a figure as any to use as a guide figure for basic JOESCO concertainer construction.

Maintenance and Repair:

There are two methods of repair which can be found in the HESCO construction guide for Engineers. An additional method would be when a cell is not badly damaged but simply requires some reinforcement. A new cell or unit can simply be placed against the damaged area and securely attached.

JOESCO Bastion units can be installed in various configurations to provide effective and economical structures which can be tailored to protect personnel, vehicles, equipment and facilities in military, peacekeeping, humanitarian and civilian operations.

JOESCO bastion units are delivered flat-packed and is manufactured in 12 size from the smallest unit. QS2 to the largest unit, the QS7. It is constructed with either 4mm or 5mm galvanized steel weld mesh, depending on the cell size and lined with a 3mm non-woven polypropylene geotextile.

Use of JOESCO bastion:

Wide,diverse and ranges from civil engineering with soil retaining walls, flood prevention and the prevention of coastal erosion. Military uses are considerably more diverse. JOESCO bastion units have been used in the construction ofAmmo compounds;.Noise abatement barriers;Sentry towers;Guard posts, both improvised and in kit form;Vehicle barriers;Entry control points;Blast mitigation walls;Cover from view;Protection for aircraft revetments;Protection of adjacent occupants from the accidental discharge of aircraft weapons;Protection of living accommodations;Provision of bomb shelters;Asset protection.

The list is not exhaustive. The use that which JOESCO bastion units can be put to is only limited by the user's imagination and a few construction engineering considerations

Fill material requirements:

One of the main advantages of JOESCO bastion units is its ability to be filled with almost any fill material. Only large rocks and clumps of earth should not be used.

For hastily required defensive positions almost any locally won fill material will suffice. The only material that should be avoided is that which contains large lumps that may create voids or damage the cells during the filling operation. Large pieces of material may also become dangerous pieces of shrapnel. Avoid organic material if possible but it is realized that in some tactical situations this may not be possible as it may be the only material available.

The users of a particular fill material is going to dependent on one or more of the following: the type of material available;the length of time the structure is likely to be employed;the perceived threat;the handling equipment available

If during the planning of the structure it is believed that it is to be in place for a time exceeding 6 months it is essential that a material with good construction characteristics is chosen. Well graded sand with low tines content, or crushed rock is ideal for long term structures.

Construction Techniques:

There are a variety of equipment types that can be utilized to fill JOESCO bastion units. Like: wheeled and tracked excavators filled with either standard buckets or clam-shell grabs;Tipper truck/dump trucks fitted with lorry loader grab attachments;Concrete skips lifted by cranes, and skid steer loaders. The simplest and easiest to use is a front end-loading shovel. Particularly when the structure is below 3.5 meters(11')high.Front end loading shovel size should be selected to match the size of bastion cell being filled. The front bucket of a backhoe loader is suitable for all cells up to QS1 in size.

Many factors will effect the time and numbers of operatives that it takes to construct any given structure, but the more common ones are: Availability of resources and manpower;Haul distance from stockpile for the fill material

.Accessibility and ground conditions;Type of JOESCO bastion unit being used;Experience of the operatives with the system and the structure being built

The key to working out the quantity of manpower required:Ascertain time available for the construction;Calculate the construction time with 4 men and loading equipment.This is your basic construction figure, if you cannot achieve completion within the given time frame then an increase in manpower and equipment is required.

For basic linear construction of 2 JOESCO bastion QS1 unit of 10.6m length, 10 cells, allow 20 minutes using one loading shovel and 4 men. This includes unpacking from a pallet, bouncing the cells out and filling. This is as good a figure as any to use as a guide figure for basic JOESCO concertainer construction.

Maintenance and Repair:

There are two methods of repair which can be found in the HESCO construction guide for Engineers. An additional method would be when a cell is not badly damaged but simply requires some reinforcement. A new cell or unit can simply be placed against the damaged area and securely attached.

JOESCO Bastion units can be installed in various configurations to provide effective and economical structures which can be tailored to protect personnel, vehicles, equipment and facilities in military, peacekeeping, humanitarian and civilian operations.

JOESCO bastion units are delivered flat-packed and is manufactured in 12 size from the smallest unit. QS2 to the largest unit, the QS7. It is constructed with either 4mm or 5mm galvanized steel weld mesh, depending on the cell size and lined with a 3mm non-woven polypropylene geotextile.

Use of JOESCO bastion:

Wide,diverse and ranges from civil engineering with soil retaining walls, flood prevention and the prevention of coastal erosion. Military uses are considerably more diverse. JOESCO bastion units have been used in the construction ofAmmo compounds;.Noise abatement barriers;Sentry towers;Guard posts, both improvised and in kit form;Vehicle barriers;Entry control points;Blast mitigation walls;Cover from view;Protection for aircraft revetments;Protection of adjacent occupants from the accidental discharge of aircraft weapons;Protection of living accommodations;Provision of bomb shelters;Asset protection.

The list is not exhaustive. The use that which JOESCO bastion units can be put to is only limited by the user's imagination and a few construction engineering considerations

Fill material requirements:

One of the main advantages of JOESCO bastion units is its ability to be filled with almost any fill material. Only large rocks and clumps of earth should not be used.

For hastily required defensive positions almost any locally won fill material will suffice. The only material that should be avoided is that which contains large lumps that may create voids or damage the cells during the filling operation. Large pieces of material may also become dangerous pieces of shrapnel. Avoid organic material if possible but it is realized that in some tactical situations this may not be possible as it may be the only material available.

The users of a particular fill material is going to dependent on one or more of the following: the type of material available;the length of time the structure is likely to be employed;the perceived threat;the handling equipment available

If during the planning of the structure it is believed that it is to be in place for a time exceeding 6 months it is essential that a material with good construction characteristics is chosen. Well graded sand with low tines content, or crushed rock is ideal for long term structures.

Construction Techniques:

There are a variety of equipment types that can be utilized to fill JOESCO bastion units. Like: wheeled and tracked excavators filled with either standard buckets or clam-shell grabs;Tipper truck/dump trucks fitted with lorry loader grab attachments;Concrete skips lifted by cranes, and skid steer loaders. The simplest and easiest to use is a front end-loading shovel. Particularly when the structure is below 3.5 meters(11')high.Front end loading shovel size should be selected to match the size of bastion cell being filled. The front bucket of a backhoe loader is suitable for all cells up to QS1 in size.

Many factors will effect the time and numbers of operatives that it takes to construct any given structure, but the more common ones are: Availability of resources and manpower;Haul distance from stockpile for the fill material

.Accessibility and ground conditions;Type of JOESCO bastion unit being used;Experience of the operatives with the system and the structure being built

The key to working out the quantity of manpower required:Ascertain time available for the construction;Calculate the construction time with 4 men and loading equipment.This is your basic construction figure, if you cannot achieve completion within the given time frame then an increase in manpower and equipment is required.

For basic linear construction of 2 JOESCO bastion QS1 unit of 10.6m length, 10 cells, allow 20 minutes using one loading shovel and 4 men. This includes unpacking from a pallet, bouncing the cells out and filling. This is as good a figure as any to use as a guide figure for basic JOESCO concertainer construction.

Maintenance and Repair:

There are two methods of repair which can be found in the HESCO construction guide for Engineers. An additional method would be when a cell is not badly damaged but simply requires some reinforcement. A new cell or unit can simply be placed against the damaged area and securely attached.