Blanco Orion Artificial Quartz Stone Countertop

| Min. Order: | 150 Square Meter |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 500000sqm/year |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | D2003 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Technics: | Artificial |

| Surface Finishing: | Polished |

| Color: | White |

| Brand Name: | BST QUARTZ |

| Composition: | 93% Natural Quartz |

| Production Capacity: | 500000sqm/year |

| Packing: | Wooden Frame or Wooden Create by Shipment |

| Delivery Date: | 15 to 25 days for one 20'GP |

Product Description

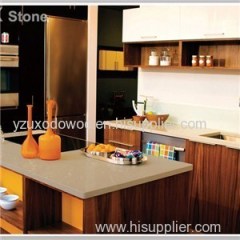

With a natural stone look and high hardness as it features. Now it's quite a upcoming trend that more kitchen builders and designers favor engineering quartz stone with marble look.

BST Quartz engineering stone is a very hard material and can give you a natural stone look with consistent color and texture throughout the engineering quartz countertop. BST Quartz engineering stone is easy to maintain and doesn't need much more daily maintenance and annual sealing required by natural stone.

BESTONE share some of our top seller quartz engineering stone option with the look of it but it might be perfect for your home decor.

A veined quartz engineering stone is not trying to compete with natural stone, but replace it.

For the very first time people who lay eyes on this quartz stone D2003, would not believe that this is an ARTIFICIAL STONE, as it looks so real, so natural that makes you wonder which quarry it comes from. And once you discover this is an artificial quartz stone, you wouldn't be more surprised. And once you discover this is a quartz color that developed by Bestone, you realize that you could be more surprised.

If you are a technician, you may be thinking how good is the quality control of the color.

If you are a designer, you may be thinking how good is the combination of color and veins.

If you are a user, you may be thinking why you didn't find it earlier.

What is BST Quartz Stone?

Quartz stone is made from 93% natural quartz+5% resin+2% pigment, which is widely used for kitchen countertops,bathroom and vanity tops, and floor tiles.

Ingredient | Natural Quartz | 93% (purified) |

Unsaturated polyester resin | 5% | |

Color and antibiotic substance | 2% | |

Slab Size | 3000*1400mm, 3200*1600mm, other sizes available | |

Thickness | 12, 15, 18, 20, 25, 30mm | |

Cut-to-size | 12, 15, 18, 20, 25, 30mm | |

How is BST Quartz Stone made?

1.Classified & Purify

Raw materials are classified and purified to ensure the quality before mixing.

2.Mixing

Raw materials are fed into mixers and blended together. Different colors have different time-table.

3.Molding & Pressing

The mixture is poured into mold and formed into slab sizes, then pressed under a condition of vacuum and vibration process.

4.Heating

The unfinished slabs are moved to the kiln and heated to give a ultimate strength and solidity.

5.Polishing

Slabs are then gauged, calibrated and polished.

6.Quality Inspection

Slabs will need to pass the quality inspection before packed and labeled.

What colors of quartz stone does BESTONE supply?

BESTONE has over 150 quartz stone colors with standard slab sizes like 3200 x 1600mm (126" x 63") and 3000 x 1400mm (118" x 55"), as well as available customized sizes 2500~3200mm x 1200~1600mm, in thickness of12/15/18/20/25/30mm. A wide range of colors and patterns such as Marble Imitation, Calacatta, Pure, Solid andMultiple Colors, as well as Mirror and Zircon Series give us a very competitive and leading position in the global market.

Our Company

BESTONE HIGH TECH MATERIALS CO., LTD. (BST Quartz) is an outstanding developer and manufacturer of engineered quartz stone slabs for 9 years. Boasting a dedicated team of over 200 members devoting to R & D, production, marketing and after-sales service for the quartz stone products and covering an area of 30,000 Sqm, at present BESTONE has three sets of fully automatic production lines for quartz stone slabs, which enable us to achieve the production capacity more than 30,000 Sqm per month. As the pioneer and leader in the industry, we have been exploring and developing the overseas markets since last 7 years. Our products are mainly sold to Australia, Canada,USA, Europe, Middle East, South America, and so on.

BESTONE B/L evidence as follow.

Company News

Related Products

D5110 Alpine Mist

D2001 Misty Carrara

D6131 Bianco Drift

FAQ

1. Where should the quartz stone be used?

Quartz stone must be used indoor such as kitchen worktops, bathroom and vanity tops and floor tiles, where are not exposed to direct sunshine.

2. Why should we use quartz stone other than natural stone?

Compared with natural stone, quartz stone has higher density and hardness, less water absorption, more durable and less maintenance, and better consistent color tone.

3. How should the quartz stone slabs be stocked temporarily?

The quartz stone slabs must not be exposed to the sunshine directly, and slabs must be erected vertically.

4. Is BESTONE trustable and reliable?

Reputation is the life of BESTONE who is verified by Alibaba and his third party. All customers are warmly welcome to visit BESTONE before ordering, and BESTONE would visit customers regularly for better understanding and support to customers.

5. Is BESTONE professional and experienced?

BESTONE has been exporting the quartz stone slabs and prefabricated tops globally for over 10 years, with 0 complaint and dissatisfaction.

6. Has BESTONE ever taken part in any exhibition?

Every year BESTONE takes part in exhibitions in USA, Europe, Dubai, Brazil, Asia, and so on.

7. Is it possible to inspect the cargos in BESTONE factory before loading?

Yes, all customers are warmly welcome to inspect the cargos before loading.

8. What information should the customers provide to BESTONE for making the prefabricated tops?

The customers should provide shop drawings or hand-written sketch with details of dimension and edge profile and exact quantity.

9. How does BESTONE make the sink cutout?

BESTONE makes the sink cutout by CNC cutting machine with perfect sizes and fine finishing.