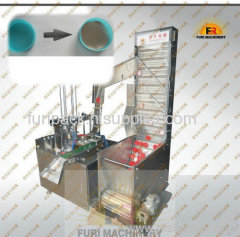

Liner Seal inserting & lining machine

| Min. Order: | 1 Pair |

|---|---|

| Payment Terms: | L/C, T/T |

| Place of Origin: | Seoul |

Company Profile

| Location: | South Korea |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | JMC1 |

|---|---|

| Feature: | Non-Refillable |

| Type: | Others |

| Material: | PP |

| Usage: | Bottles |

| Packing: | Wooden case packaging & Cargo shipment |

| Delivery Date: | Shipping within 3 month |

Product Description

Since our company was founded in 1979, we have been constantly manufacturing the bottle cap producing machines, which produce the excellent bottle caps as well as meet our customer's requirements.

JOONGSAN has been specialized in manufacturing bottle cap machine, and we have rich experience in the world market.

We cooperate with the customer from the birth of an idea until the final solution.

- Get great feedback from domestic and abroad market.

For more than 35 years, we have exported our machines to India, Pakistan, Egypt, Japan, Phillippines, Vietnam, Chile, Cambodia, Russia and so on.

In addition to these abroad countries, many domestic companies are using our machines.

We are steadily trying to keep abreast to the high technology level and to obtain the superior position in the world market.

We are able to manufacture many kinds of CAP LINING MACHINE.

The main function of cap lining machines is to automatically insert the aluminum foil gasket or the PE foam gasket into the cap, which achieves automatic liner inserting and prevents the liner from being contaminated by manual liner inserting.

Automatic operation is not only environmentally friendly and sanitary, but also substantially improves the working efficiency of manufacturers.

This machine is an ideal liner inserting machine which is widely applied in cap factories, liner factories, pharmaceutical factories, food products factories, daily chemical factories, packing factories, and so on.

Within our series of machines, we possess different designs which cover various production requirements including cutting power, speed, sizes and shapes of caps to process.

- Operation principle

Cut the reeled liner materials into specified size and simultaneously insert the precut liner into the cap.

Finally, the liner pressing unit press the liner to the bottom of the cap.

This is the whole process of simultaneous liner cutting and liner inserting.

The liner is supplied from the feeder. The machine inserts it at the same time as soon as it cuts.

The machine alarms and stops automatically when there is no cap on the cap conveyor belt or when there is no reeled liner material.

- All machines are custom-made products, developed and produced according to our customer's demands.

- The capacity can be modified anytime.

(quantity per min, cap size, cap materials)

- All machines are fabricated in Korea and assembled in abroad.

- While setting up the machine, we will have enough time in order to train your worker with the way to operate it exactly.

- All our machines are controlled by automatic system so as to deal with it more easy.

Additionally, it will help to save labor cost and improve quality.

(touch screen, inspection camera)

- All functions can be operated and set on the touch screen, simple and convenient.

- Reasonable price and professional service will be offered.

Thanks and Best Regards.

Please quote to this :

Skype ID : bangkb