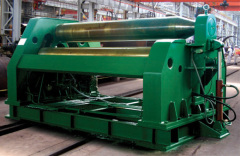

Thick sheet Plastic Forming Machine

| Min. Order: | 1 unit |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 20unit/month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | NF-HP |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | ABS |

| Use: | Film Crusher |

| Shaft Design: | Others |

| Brand Name: | Nanfang Electric |

| Power: | 220v/380v |

| Capacity: | 700times/hour |

| Automatic: | high speed |

| Production Capacity: | 20unit/month |

| Packing: | 1unit/20ft |

| Delivery Date: | 20days |

Product Description

Parameters

Model No.: | NF-HP |

Forming Length: | 1250mm |

Forming Width: | 560mm |

Forming Height: | 300mm |

Material Thickness: | 1-8mm |

Speed : : | 14 times/min |

Power Source : : | 380V /220V-50Hz |

Air pressure : | 100m3/h |

Machine Max.Power Rate: | 45KW |

Net Weight: | 3000kg |

Application:

1. suitable for thick materials of ABS,PP,PS, EPS, HIPS, PVC etc

2. Vacuum forming various types of plastic products.

3. Making plastic products such as Car Accessories, Ship Accessories, Electric Appliance Linner, Door Plank, Lighting, Bag, Suitcases, Case, Decorations, Furniture, Sanitary Appliance, Toy, Stationery, Sports Equipment, Art Advertising, Traffic Sign and Tray Liner etc.

Specifications

This plastic forming machine is used for heating and softening the thermoplastic of the plastic sheet, and then vaccum formed in the mould after being blown. Work process: Manual operation supply material –Clip—Heating—Blow-up—Vacuumn Forming—Core pulling—Reset—Cooling—Demoulding—take out products.

Feature:

1. This machine adopts pneumatic, mechanical, electrical combination, to achieve the clip, heating, molding and other automatic work. High production efficiency, easy to operate.

2. Easy to feed material and less waste of material.

3. Suitable for male punch molding and high-depth products molding in stability quality.

4. Newest style of far infrared heating element heater with automatic temperature control, evenly heated and low energy consumption.

5. With air cooling and automized water spray to make the products cooled fast and molding well to reduce defective products.

6. Electric control to make the operation more simplify and conveniece and can adapt to different positions of different angles of operation.

7. The height of the upper mould adopts the limit adjustment of the motor, so that the adjustment is convenient and quick.

.jpg)

.jpg)