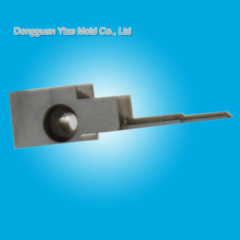

Micro Precision Punch for Mold Parts

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T |

| Supply Ability: | 1000 per Month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

Product Detail

| Model No.: | HG-Punch |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product Material: | Metal |

| Product: | Vehicle Mould |

| Shaping Mode: | Punching Mold |

| Brand Name: | HG |

| Stamping Mold Components: | Sheet Metal Stamping Mold Parts |

| Punch Mold Parts: | Fine Blanking Tooling Parts |

| Plastic Parts: | Progressive Die Spare Parts |

| HS Code: | 8207300090 |

| Punch Diameter: | 0.153mm |

| Production Capacity: | 1000 per Month |

| Packing: | carton package |

| Delivery Date: | 10 days |

Product Description

1 | Item | description |

2 | Name | High Accuracy Tunsten Carbide Punch |

3 | Process Machine | Grinding machine, Sodick Wire cut machine |

4 | Measuring instruments | Projector, Toolmaker Microscope |

5 | Contour tolerance | ±0.001 |

6 | Profile tolerance | ±0.002 |

7 | Hole tolerance | ±0.003 |

8 | First trial place order | Track service, anything is wrong, we will take immediate measures |

9 | Quotation | Once receive RFQ, we will reply you in 2 hours |

10 | Delivery time | 10-20 days after confirm the order |

11 | Material | CF-H40S, RD30,RD50,ASP23, AF1,,etc. |

12 | Design | Non-standard(according to customers' request), Standard |

13 | Minimum order | Products are non-standard parts, one piece is acceptable. |

14 | Packing | Carton, attached Quality Control report |

What we do:

1) Plastic mould components(metal mold punch; stamping mold spare parts; progressive die components; ejector pin, ejector sleeves,locating ring,interlock,ect).

2) Press die mould component(guide pillar,guide bush,punch ect).

3) Non-standard mould parts, Precision parts according to customer draws.

Why choose HG:

•Guaranteed Precision.

•On time delivery

•High quality&competitive price.

•OEM is available

•Close tolerances.

•Long service life.

•Various material choices.

•100% whole range inspection.

•Excellent customer support.

Packing:

1. Inner Packing: Bubble Bag;

2. Outer Packing: Carton / Wooden Case;

3. According to customers' requirement, keep product preventing from damage.

Please specify the details as follow when you inqury,thanks.

1,The shape of mould parts you need.

2,The material of mould parts you want to use.

3,The products size ,for example:M2.0,D 14*25.

4,The surface coating type ,for example:Tin,Ticn

5,It is the best to provide your own drawings,3D or CAD.

You Might Also Like

precision die mold parts/ ejector pin /core pin /mold part/ mold components/guide pin/guide bush/cooling connector

precision die mold parts/ ejector pin /core pin /mold part/ mold components/guide pin/guide bush/cooling connector

precision die mold parts/ ejector pin /core pin /mold part/ mold components/guide pin/guide bush/cooling connector

precision die mold parts/ ejector pin /core pin /mold part/ mold components/guide pin/guide bush/cooling connector