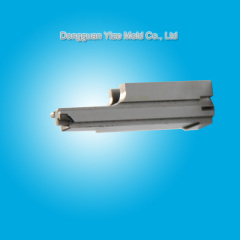

Tungsten Carbide Mold Punch

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF,DDP,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 1000 |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Product Material: | Metal |

| Product: | Household Appliance |

| Shaping Mode: | Punching Mold |

| Brand Name: | HG |

| Motor Core Die: | Motor Core Mold |

| Production Capacity: | 1000 |

| Packing: | carton package |

| Delivery Date: | 10 days |

Product Description

Precision Punch and Die for mold:

We are offering Industrial Punches which are duly made of High Speed Steel M-2 grade (cylindrical head,CSK type, straight) as per DIN: 9861/ IS 4296 standard.This pins are hardened to 64 degree HRC and grounded to close tolerances of (-0.01mm). Used for Die and moulds manufacturing, these can be re-faced or re-tipped while still controlling an exact fit to existing dies when damaged. Our punches are provided to our clients in customized specifications as per their varied requirements.

Step Punch: Our step punches are widely used in metal fabrication industries. These are ideal for pressing through sheets of metals and into a die to form desired shapes on the metals. Widely used for its efficient and long-lasting performance, our range is cost effective.

Square Punch: These square punches serve numerous applications in the engineering industries all over the world. Our range is available in rod types and has a shaped tip at one end. The other end of the punch has a blunt butt that is struck by a hammer to put force on it during the pressing process.

Double Step Punch: These double step punches are capable of handling multiple die casting application at one time. Used to manufacture different types of metal shapes, our range is made of various ferrous and non-ferrous material.

Special Punches: Our HSS punches are available in diameter (in 0.1mm in progression) from 0.5mm to 25.4 mm and different lengths of 25 mm, 30 mm, 35 mm, 50 mm, 70mm,80mm, 100mm and upto 200mm more to meet the diverse needs of the PCB industry. Further, we also offer these punches in different tolerances, material and technical specifications of the clients.

Piercing Punches: These punches can efficiently minimize wear, flashing, wicking and dishing. Our HSS punches are truly hardened to the core 640 ± 2HRC with the head annealed 450 ± 5HRC. These pins are precision smooth finished lapped with maintaining tolerance of (-0.005mm) to (-0.01mm) for smooth running in dies and moulds. However, tailor made tolerance is also made available from our reputed manufacturers.

We have the most competitive rates in this industry with consistent quality and most of the sizes are ready available in stock.

It's also available for the specification with your own special design.