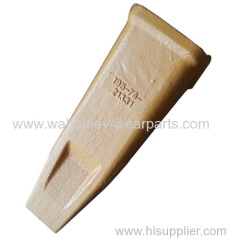

Spare Parts Volvo Bucket Teeth

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 10000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 1455-3243 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Construction machinery |

| Better Surface: | Better Surface |

| Spare Parts Forging Teeth: | Ground Engaging Tools |

| Material: | Alloy Steel |

| Market: | Global |

| Desc: | bucket teeth |

| Equipment type: | EXCAVATOR |

| Condition for Scale bucket tooth: | New |

| Impact: | above 20J |

| HARDNESS: | HRC48-52 |

| Production Capacity: | 10000 |

| Packing: | wooden case |

| Delivery Date: | 10 days |

Product Description

FORGING BUCKET TOOTH FOR VOLVO MACHINE

Application of high manganese steel bucket teeth in

In order to overcome the traditional high manganese steel bucket tooth problems, researchers in the aspects of strengthening and toughening of high manganese steel do a lot of work, mainly through alloying or micro alloying method and improve its strength and wear resistance.

Mo added on the common high manganese steel based on the composition, Cr, V, Ti, etc. carbide forming elements, thus changing the distribution of carbides in high manganese steel form granular carbides, the dispersed in the matrix of austenite, so as to improve the strength and wear resistance.

Such as the American ace hoppers teeth and aysc0 company in common high manganese steel bucket teeth of component based, through alloying method, were added to the 2% Cr, 1% ~ 2 1%mo a modified high manganese steel bucket teeth. Compared with common high manganese steel, the yield strength increased 10% to 30%.

In addition, the use of micro alloying (Ti, joined V, Nb etc.) high manganese steel improved the strength is 30% higher than ordinary high manganese steel.

In our country by micro alloying method in high manganese steel by adding V, Ti, Mo alloy elements, and dispersion hardening heat treatment, the micro alloy carbides and on the matrix of austenite, thereby improving the abrasion resistance, bucket tooth life increased by 70% ~ 100%.

Mining practice shows that the alloying and micro alloying high manganese steel, both in high impact stress or under low stress, with good wear resistance. But the alloying elements Cr, Ni, Mo addition increased the cost, especially rare and precious elements Ni, Cr restricts the development of this kind of steel.

Your Satisfaction is our ultimate goal !