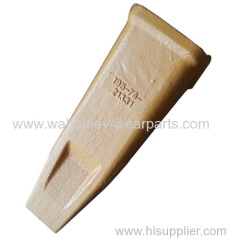

Excavator Digging Forged Volvo Bucket Teeth

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 10000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 1171-00041RC |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Construction machinery |

| Better Surface: | Better Surface |

| Spare Parts Forging Teeth: | Ground Engaging Tools |

| Material: | Alloy Steel |

| Market: | Global |

| Desc: | bucket teeth |

| Equipment type: | EXCAVATOR |

| Condition for Scale bucket tooth: | New |

| Impact: | above 20J |

| HARDNESS: | HRC48-52 |

| Production Capacity: | 10000 |

| Packing: | wooden case |

| Delivery Date: | 10 days |

Product Description

Qur company specializing in the production of machinery bucket teeth, the factory uses a low carbon environmental protection forging technology, forging a high density, porosity, smooth surface, good toughness.

Provide a variety of forging bucket tooth type, such as the need for this type of forging bucket tooth please fax the drawings and requirements or telephone my factory.

Rapid prototyping of bucket tooth fused deposition

1 .Principles of Technology

FDM-fused deposition modeling process is thermoplastic material hot melt, dry contact. In computer control layer by layer deposition process.

Material first pumped into filamentous. Through the wire feeding mechanism for feeding nozzle, in the spray nozzle is heated until the molten state. Nozzle along the cross-section parts round which and filling soft tracks. At the same time, the molten material extrusion, material rapid solidification. Wells and Zhou Tian materials dry. Layers stacked. Like eventually made machine pre designed components.

2 .Process features and Applications

(1) FDM process without laser. The operation is simple and easy, and has no pollution to the environment.

(2) the forming process needs to be constructed, but the required supporting components can be used in another nozzle to form another material, which is not easy to remove.

(3) the disadvantage of this process is that the structure is not easy to manufacture complex parts. The precision of the forming parts is low, the surface quality of a difference t forming efficiency is low, which is not suitable for the manufacture of large parts.

Fused deposition RP wins the materials used in forming mainly ABS plastic, stone clam, low melting point metal, rubber roll, Yi thermoplastic wire.

Can be used to side made precision investment chess with Zelda type casting. Manufacturing new product perception evaluation and performance side to be tested samples, structure analysis and assembling the sparetime school for adults of sample.

And the woman playing single or small batch t molding mold production.

FORGING ROCK CHISEL BUCKET TEETH

CASTING BUCKET TEETH FOR VOLVO MACHINE