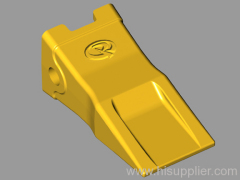

Forging Process Daewoo Bucket Teeth

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 10000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 2713-1236RC |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Construction machinery |

| Better Surface: | Better Surface |

| Spare Parts Forging Teeth: | Ground Engaging Tools |

| Material: | Alloy Steel |

| Market: | Global |

| Desc: | bucket teeth |

| Equipment type: | EXCAVATOR |

| Condition for Scale bucket tooth: | New |

| Impact: | above 20J |

| HARDNESS: | HRC48-52 |

| Production Capacity: | 10000 |

| Packing: | wooden case |

| Delivery Date: | 10 days |

Product Description

Our Services:

Contact us if you would like any further details or information on any of High quality machinery spare parts , and we will be more than happy to answer any questions that you may have.

Excavator Forged Bucket Teeth

Bucket teeth description

The bucket teeth are forged, not casting. They are used for a wide range of excavators, for example Komatsu, Daewoo, Caterpillar, Volvo, Kobelco, Hyundai etc.

Forging is kind of method which uses forging machine to press the metal blank to make it produce plastic deformationand obtain a certain mechanical property, shape and size. Forging can eliminate the defection of as-cast loose during metallurgy process and improve the microstructure. The mechanical property of forging bucket teeth is generally better than that of the same material of casting bucket teeth, because forging craftsmanship can keep the intact metal streamline.

ROCK CHISEL DESIGN FOR HARD WORKING CONDITION

BUCKET TEETH WITH FORGING PROCESS

CHINA BAVMA FAIR BOOTH E5-359