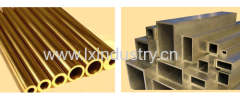

Brass Tube for auto fitting and bathroom accessories

| Min. Order: | 1 Metric Ton |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 5000 t/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | LX-B |

|---|---|

| Means of Transport: | Ocean, Land |

| Alloy No.: | C27400, C27200, C27000, C26800, C2600 |

| Size: | 1/4''-3'' |

| Out diameter: | 1-150mm |

| Wall Thickness: | 0.2-10mm |

| Length: | less than 6000mm |

| Production Capacity: | 5000 t/month |

| Packing: | fumigated wooden case or carton |

| Delivery Date: | 25-30 days after receiving the deposit |

Product Description

| Brass Tube and Pipe | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass pipe widely used in bathroom accessories, hardware tools manufacturing, auto fittings, heating elements, construction, ship building etc. We offer brass pipe as clients' requirements, manufacturing according to main countries' standards, such as ASTM B 135-02, ASTM B111, GBT 5231-2001, BS EN 13600-2002, etc. 1. Those alloys are specified having the following nominal compositions:

2. Specification Available:

3. Mechanical Properties of Drawn Temper Tube as following:

4. Mechanical Properties of Annealed Temper Tube as following:

A Although no Min. Grain size is specified, the products must nevertheless have a fully recrystallized grain structure

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Back | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||