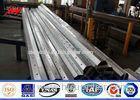

Slip Joint Tapered Steel Pole

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Telecom Tower, Communication Tower, Radio /TV Tower , Torch Tower , Dem |

Product Description

1. Voltage range: 10KV-750KV 2. Material: Q345B/ASTM A572 Gr50,Website:http://www.transmission-towers.com, Q235B/ASTM A36, Q420B/ASTM A572 Gr 60, Q460B/ASTM A572 Gr 653. Welding: 1 ) CO2 welding and submerged arc auto welding or other methods as AWS D1.12 ) Welded seam shall be full penetration and grinded.3 ) The welded product has no fissure, scar, overlap, layer or other defects.4.Surface Treatment: Hot Dip Galvanization or paintedThe tower galvanized as per ASTM A-123. Fasten parts as ASTM A-153,painting of international standard.5. MOQ: 1*40FT Container. 6. Price Term: EXW, FOB, CFR or CIF.7. Payment Term: 30% by T/T as deposit , balance by T/T or irrevocable L/C at sight before shipment. Other payment way can be negotiated.8. Delivery Lead Time: 30days after receiving deposit or as client's requirements.9. Package: nude or bulk packing, bundle, wrapped by galvanized steel strap , woven bags ,mat ,straw bale or bubble plastic ,steel wire, plywood or according to client's requirement.10.Lifetime: 50years11.Warranty: 15 years12.OEM is accepted.

Terms

Details

Voltage

10 KV ~750 KV

Usage

Electricity distribution,Power Transmission

Category

Tubular type ,suspention pole,turning pole,terminal pole

Material Grade

Usually Q345B/A572, Gr 50,60, 65 minimum yield strength>=345n/mm2 as main materialQ235B/ASTM36,minimum yield strength>=235n/mm2- as auxiliary material.

Surface treatment

Hot dip galvanized as ASTM A- 123, color polyester power ,painting or any other standard by client required.

Design Load (Kg)

300~ 3000Kg

Marking

Name plate through rivert or danger plate,glue ,engrave ,emboss as per customer requirement

Design

We can design free of charge if Qty is numerous, client should supply the design parameters.

Standards

ISO 9001:2008

Joint of Poles or lattice or angular towers

Lap connection or flange connection, lattice tower by bolts and nuts.

Length of per section

Within 14m once forming without slip joint

Welding

Submerged arc welding , internal and external double welding makes the welding seam beautiful in shape, CO2 weldingWelding Standard :AWS D 1.1 ( American Welding Society )

Thickness

1 mm to 50 mm

Packages

as normal cover by Mat or straw bale at the top and bottom ,we can following by client required , each 40HC or OT can load how many will calculate based on the actually specification and data.

While incoming QC guards inferior components from going into production lines,outgoing QC reassures that only qualified products leave our factory. 100% quality checking is carried out at our offline W-Inspection line to guarantee zero-defect items. Every Production process is equipped with full-time quality inspector. They have to inspect all of the parts' dimension and accuracy according to national standard or international standard to ensure all of the parts are okay to go to next process. And the inspector should calculate the quantity of each bundle according to the packing list to make sure the quantity is right ,packing properly and the surface is smooth.