Adhesive Fiber Creasing Matrix

Company Profile

| Location: | Beijing, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Creasing Matrix , Paper Cutting Knife, Rubber Blanket, Ejection Rubber |

Product Description

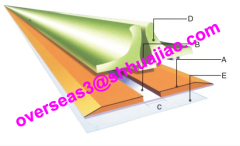

Adhesive Fiber Creasing Matrix A fiber based matrix used on auto platens; especially suitable for fragile or recycled board.

Combining vulcanized fiber with modern materials,Website:http://www.bjgraphic.net, Graphic Fiber series offers up to 2 or 3 times the durability of plastic matrices.Quick Details Place of Origin: Beijing, China (Mainland)Brand Name: GraphicModel Number: GRB0.4x1.5 FChannel Height: 0.4 mmChannel Width:1.5 mmLocator Color: WhiteMatrix Color: GreenApplication: For box makingMachines: Semi-Auto/Full Auto PlatensCertificate: SGSPackaging & Delivery Packaging Details:70cm/pc, 50pcs/box, 1.3kgs/box, 10boxes/carton, Carton: 73 x 22 x 21cm(length x width x height), 400-700boxes/palletDelivery Detail:Within 5-15 days upon receipt of paymentFeatures: Precise locator – ensures perfect registration each time.Low profile chamfer – board flows freely over the matrix; board marking is reduced.Yellow Finger lift adhesive tape– backing paper easily and quickly removed.High tolerance & accurate channel depth and width.Removes cleanly from the plate after use, will not move about during machine run, quite sticky.Full range of sizes available to suit all board types, internal chamfers, for low quality boards, and off-centers for close creasing rule.High quality fiber construction, Extremely durable.Notes: OEM and special sizes are available upon customer's demands.Size Table H x W mm H×W mm H×W mm H×W mm H×W mm GRB 0.3×0.8FGRB 0.4 x 0.8FGRB 0.5 x 1.0FGRB 0.6 x 2.3FGRB 0.8 x 2.5FGRB 0.3×1.0FGRB 0.4 x 1.0FGRB 0.5 x 1.2FGRB 0.6 x 2.5FGRB 0.8 x 2.7FGRB 0.3×1.2FGRB 0.4 x 1.1FGRB 0.5 x 1.3FGRB 0.6 x 3.0FGRB 0.8 x 3.0FGRB 0.3×1.3FGRB 0.4 x 1.2FGRB 0.5 x1.4FGRB 0.7 x 2.3FGRB 0.3×1.4FGRB 0.4 x 1.3FGRB 0.5 x 1.5FGRB 0.7 x 2.5FGRB 0.3×1.5FGRB 0.4 x 1.4FGRB 0.5 x 1.6FGRB 0.7 x 3.0FGRB 0.3×1.6FGRB 0.4 x 1.5FGRB 0.5 x 1.7FGRB 0.7 x 3.5FOperation Procedure Cardboard Weight(g) Thickness of Cardboard(mm) The height of Creasing Rules(mm) 23.50 23.40 23.30 23.20 23.10 23.00 200 0.28mm 0.3×1.0 0.4×1.0 250 0.35mm 0.3×1.2 0.4×1.2 0.5×1.2 300 0.42mm 0.3×1.3 0.4×1.3 0.5×1.4 350 0.50mm 0.4×1.4 0.5×1.5 0.6×1.5 400 0.56mm 0.5×1.6 0.6×1.6 450 0.63mm 0.5×1.7 0.6×1.7 0.7×1.7 500 0.70mm 0.7×1.7 0.8×1.7 Notes: the specifications above are only recommendation, among which the specifications marked with are recommended to choose firstly.1. Measure the length of the creasing rule 2. Mark the measurement and cut the matrix 3. Mount the cutting piece into the creasing rule with locator 4. Remove all of the backing tapes 5. Transfer the matrix to the die cutting steel plate 6. Remove all of the locators 7. Miter the sharp angle Calculation Formula Method to choose creasing matrix size for cardboard paper. Size table ( subject to 23.8 mm die-cutting rules)For instance: the thickness of the cardboard: 0.52mm; the thickness of creasing rules: 0.71mm, according to calculation formula: A=0.52≈0.5(mm); B=0.52 x 1.5 +0.71 = 1.49 ≈1.5(mm),so we should choose the size of 0.5 x 1.5. Method to choose creasing matrix size for corrugated paper. Size table ( subject to 23.8 mm die-cutting rules) Corrugated Paper Thickness of corrugated paper after compression Height of creasing rule Choice of creasing matrix(thickness of creasing rule is 1.05mm) Choice of creasing matrix(thickness of creasing rule is 1.42mm) F-Flute 0.50mm 23.20mm 0.5×1.7 E- Flute 0.65mm 23.10mm 0.7×2.3 _ E- Flute 0.75mm 23.00mm 0.8×2.5 _ B- Flute 0.85mm 22.90mm 0.8×2.7 0.8×3.2 B- Flute 0.95mm 22.80mm 1.0×3.0 1.0×3.5 C- Flute 1.05mm 22.70mm 1.0×3.2 1.0×3.5 C- Flute 1.15mm 22.60mm _ 1.0×4.0 Remarks: the above blanks just for reference and the exact specification suitable for your job should be chosen according to your actual conditions and material thickness.