Feiyide Automatic Rack Electroplating Production Line for Zinc Silver Plating With Best Price

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T, WU, Money Gram |

| Supply Ability: | 1 Sets /Month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Hardware & Electronics Electroplating Machine, Oxidizing Equipment, Electrophoresis Equipment, Electroplating Barrel |

Product Detail

| Model No.: | FYD-AL |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | Others |

| Raw Material: | Others |

| Machine Type: | Others |

| Extra Services: | Others |

| Automation: | Automatic |

| Certification: | ISO 9001:2000 |

| Material / Metal Processed: | Others |

| Brand Name: | Feiyide |

| Application: | Zinc Silver Plating |

| Available for: | Hardware Parts Plating |

| Production Capacity: | More Than 10000 Piece |

| Plating Position: | Dipping Position |

| Material of Tank: | PP PVC |

| Control System: | PLC Controlling |

| Surrounding Equipment: | Pipe Blower |

| Heating Model: | Electronic Heating |

| MOQ: | 1 Set |

| Shipping: | By sea or air |

| Production Capacity: | 1 Sets /Month |

| Packing: | Wooden boxes |

| Delivery Date: | 30 Days after deposit |

Product Description

Feiyide Automatic Rack Electroplating Production Line for Zinc Silver Plating With Best Price

Production description

features

1 stable and quiet running

2 continouous Production and high quantity

3 systemic design

4 PLC controlling system

main structure

more details

| 1application | zinc silver plating |

| 2available for | hardware parts plating |

| 3controlling system | PLC controlling system |

| 4surrounding equipment | air blower pipe |

| 5material of transporter | SUS 304 |

| 6shipping | by sea or air |

| 7pachaging | wooden boxes |

| 8other service | process design and chemical liquid supply |

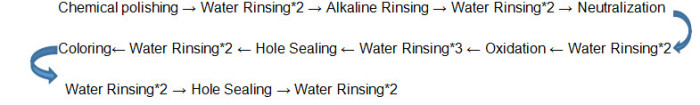

example of process

This Vertical Automatic Electroplating Line has following advantages

1 PLC controlling system

2 Stable and quiet running

3 Adjustable runningtime and speed

4 Continuous production and high quantity

5 Systemic design order

Company information

we are specialized in making plating machines such as plating line, plating tank, plating barrel and water/gas treatment plant. Auxiliary equipment includes high-frequency switching power supply, filter, heater, temperature controller, titanium basket, oven, industrial water purification machine, chiller, etc.

With the innovation of technology, the general customers' support and trust, there will be developing prospects. Our company sincerely hope to achieve a win-win situation with you and create a bright future hand in hand.

Our service

We can provide you the following service:

1. Project design

2. Manufacturing

3. Installation and test

4. After-sale service

FAQ:

1.Q: We need plating machine for ×××, could you send me a quotation?

A: Because plating machine is always customized for different products, we'd like to send you quotation and make the design for you based on knowing detailed information from you first.

2.Q: What is the necessary information you need for design?

A: The plating prosess you have had, The capacity of your per products, The material, weight, size, and surface area of your per product, The thickness of plating layer, Your working hours per day, Type of salt spray test and time, Workshop dimension and so on

3.Q: What's the lead time for one project?

A: It usually would take about 15-30days for production and the time is based on specific projects.

4.Q: How can I carry out my work if I plan to set up a new plating line?

A:It would be better if we could communicate with your chemical liquid supplier on the process details first. Besides, professional engineer is anso important for your project.

Packaging and shipping

Packaging details: container with wooden package

Delivery detail:50days