EPS foam cutter machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 10 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Jinhua, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Brand Name: | Green Building |

|---|---|

| Driving method: | Ball screw driving |

| Material: | Steel frame |

| Control method: | CNC control |

| Protection: | limiting travel protection |

| Lfet and right stroke: | 3m |

| Lifting stroke: | 1.25m |

| Wire hanging length: | 2m |

| Voltage: | 80-220V(cutomized) |

| Weight: | around 1000kg |

| Waranty period: | 1 year |

| Production Capacity: | 10 sets per month |

| Packing: | wooden boxes |

| Delivery Date: | 60 days after your order |

Product Description

EPS Foam coating machine is very important machine as hot wire CNC foam cutting machine for the companies, which produce decorative architectural foam shapes. The surface of the decorative models, which has sliced by EPS blocks, should be coated with foam coat, for protect the building surface from corrosive weather conditions ( like rain, snow, hail, storm and temperature differences between day and night)

For example, you can't gain first quality product if your EPS coating machine or your mortar is wrong even if you use the best quality foam cutting machine of the world.

Therefore, all machines in your factory have important equally. It is very important for your company's achieve that you to buy the machines which are compatible and can be integrated each other.

EPS Foam Coating Bussiness

If you want to create a business which is competitive and would have great growing percentage in construction industry market, you need to produce the final products with acceptable quality.

As is known, the product should be visibly qualified for settling into the good space in your target market. So the most important thing is the surface of your decorative foam shapes model should be completely smooth and clear. Also its corners should be explicit and straight. And the last there should not be any appeared bubble on the surface of products.

A company needs a well designed EPS foam coating machine for achieving this qualified on every coating workshop. Besides a company also needs training for to formulating and assembling a foam coat which stands either elastic and stiff in a meantime. During the 7 days training that we will provide you detailed information about, usage of foam cutting machines, choosing the raw materials and all knowledges you may need in Professional manufacturing process, by specialist technician service and our training stuff. After the 7 days training, you will produce your first demo product with your raw materials in company with our trained stuff.

Foam Coating Thickness

Now, you have general knowledge about foam coating so let's tell you about a top level technical knowledge.

That how many millimeters mortar coated on to foam is as very important as quality of mortar on the foam while manufacturing decorative exterior profiles and other exterior products.

You can do coating as much as you want between 1 millimeter and 10 millimeters using our foam coating machine. (The commonest mortar thicknesses of exterior products which are preferred in good quality and economic product class around the world are 2 mm/3 mm and 4 mm.) It is not a correct approach the think that "product which has been coated thickly is always good quality."

Financial

There are two points important about that. First, you should manufacture appropriate products for climatic conditions of your country. And second, you should manufacture with proper price in price range of your target market.

Consequently, you manufacture these products because you want to gain profit.

If you manufacture thickly coated products so as to them to be in good quality and to take attention of customers, this causes manufacturing costs differentiation with your competitors and affects your competition and selling potential.

This is very important: If your customers haven't ordered special thickness such as 5-6 mm, you should coat generally 2 or 3 mm mortar also taking your competitors' mortar thickness into account. 90 percent of manufacturers around the world do coating between 2 mm-4 mm thickness.

If you live in a snowy and cold region like Canada, Scandinavia, your mortar thickness on exterior products may be 4 mm/5 mm. Much more than these thickness are extreme and aren't used without demanding specially.

Don't forget; while you are doing foam coating application, every extra 1 mm thickness increases the cost of manufacturing.

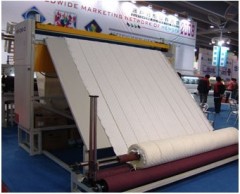

Photos

Contact

Foam Coating Machine

Home Machines Foam Coating Machine

FOAM COATING MACHINE

Eps Foam Coater Description

General Info

EPS Foam coating machine is very important machine as hot wire CNC foam cutting machine for the companies, which produce decorative architectural foam shapes. The surface of the decorative models, which has sliced by EPS blocks, should be coated with foam coat, for protect the building surface from corrosive weather conditions ( like rain, snow, hail, storm and temperature differences between day and night)

For example, you can't gain first quality product if your EPS coating machine or your mortar is wrong even if you use the best quality foam cutting machine of the world.

Therefore, all machines in your factory have important equally. It is very important for your company's achieve that you to buy the machines which are compatible and can be integrated each other.

Eps Foam Coating Introduction

EPS Foam Coating Bussiness

If you want to create a business which is competitive and would have great growing percentage in construction indus