1. Film based with finger-lift tape

2. Strong and stable glue

3. Durable plastic material

4. SGS certificate

5. Short die job

Feature:

a) The unique processing technology used by us makes our products superior than the other product at pasting and die-cutting times. The PVC based matrix can be used for 80000 times, fiber-based about 1200000 to 150000 times and paper base about 1500000 to 180000 times.

b) We use high quality material for the positioning bar with moderate flexibility-easy for operation and accurate position.

c) Imported double-side adhesive tape is easy to be cleaned after die-cut.

d) Linear mouth with good vertical degree.

All kinds of special specifications can be customized models

Specifications

Type of creasing matrix

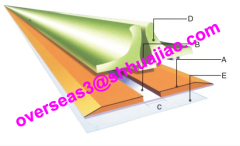

Creasing Matrix Structure

A. Thickness of creasing matrix

B. Brute mighty bottom film

C. Slot width of creasing matrix

D. Positioning plastic strip

E. Protection film.

Selection Method Of Indentation

when cutting cardboard the selection method of creasing matrix

a) Calculation method:

A=The thickness of the creasing matrix

B=The slot width of the creasing matrix

C=The thickness if the cardboard ≤d

d= The thickness of the creasing line

A≤C B=(C*1.5)+d

b) Cardboard choose table (die-cutting blade height 23.8 mm)