Coal briquette machine/ charcoal briquette machine/saw dust briquette machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets/year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | THHB-430 |

|---|---|

| Means of Transport: | Ocean |

| Color: | Customized |

| Materials of Roller: | 65Mn, 9Cr, 2Mo |

| Capacity: | 5-8t/h |

| Power: | 11-15kw |

| Warranty: | 12months |

| Production Capacity: | 100sets/year |

| Packing: | Standard packing or whole container |

| Delivery Date: | 30 days after confirm the order |

Product Description

Introduction

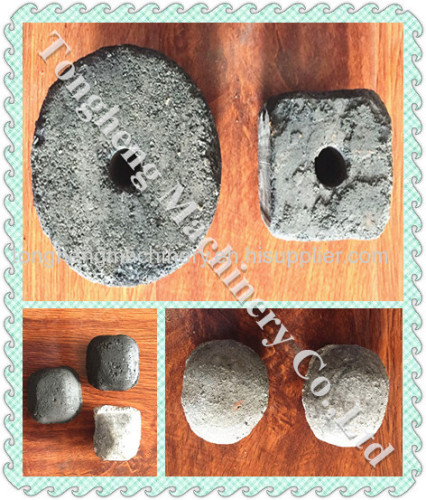

Pulverized coal molding process divided into cold molding and thermo molding, mainly to cold forming; cold molding is divided into binder forming and binder-free molding, mainly to binder forming. According to our country's situation, pulverized coal molding are most use adding a binder, mesolow, free drying, cold molding process.

Application of Coal Briquette Machine

Coal briquetting machine can be used to suppress the end of coal, iron, coke, aluminum, iron, iron oxide skin, carbon powder,charcoal powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke and other powder, powder, scrap, waste, widely used in refractory, power plants, metallurgy, chemical industry, energy, transportation, heating and other industries. The materials after pressed by the briquette machine are energy saving, easy to transport, increased its waste utilization, with good economic and social benefits.

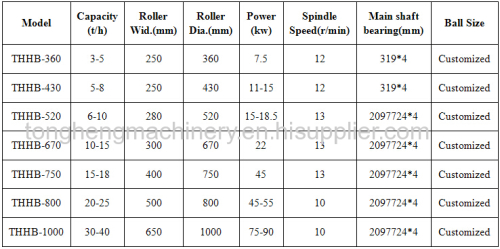

Technical Parameters