Strong pressure briquette machine for dry powder pressing

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets/year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | THQL-1000 |

|---|---|

| Means of Transport: | Ocean |

| Color: | Customized |

| Materials of Roller: | 65Mn, 9Cr, 2Mo |

| Capacity: | 30-40t/h |

| Power: | 75-90kw |

| Warranty: | 12months |

| Production Capacity: | 100sets/year |

| Packing: | Standard packing or whole container |

| Delivery Date: | 30 days after confirm the order |

Product Description

Introduction

Strong briquette machine is mainly used for - colored blocks and ferrous metal ore briquette making, directly into the furnace smelting, increase the added value. Any metallurgical industry waste materials, accessories should be on the furnace, they are all need the strong pressure briquette machine to complete. Such as: dust, mud pools, scale, slag, iron powder, aluminum ash, manganese ore, and so on.

Advantages

1, High forming rate

2, Low power consumption

3, Compact structure

4, Easy maintenance and debugging

Application

Strong pressure briquette machine is widely used in the following materials, granulation or ball press, such as aluminum powder, activated carbon, alumina, bauxite, caustic soda, charcoal, clay, coke breeze, coal, cryolite, fertilizers, plastics , limestone, pigments, urea, potassium salty and so on. The aim is to reduce dust,density control, return utilization, improve the transport properties. The design capacity is mainly used for dry powder pressed into pellet materials of the pidgeon magnesium process.

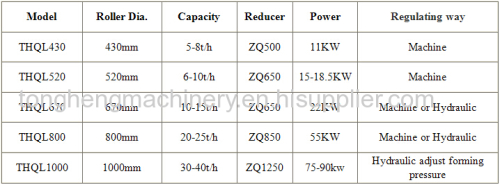

Technical Parameters