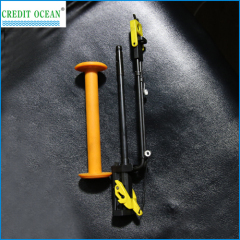

| Spindle | Bobbin size(mm) |

| AA | Φ43×113 |

| A | Φ48×140 Φ48×113 |

| AB | Φ58×180 |

| B | Φ70×210 |

| BC | Φ74×282 |

| C | Φ85×280 |

| CD | Φ70×330 |

| D | Φ100×330 |

| E | Φ130×400 |

| F | Φ225×600 |

| G | Φ335×800 |

Feature

1 for the cause of domestic high speed braiding machine noise is larger Our company technical engineer to carry on the long-term research and development, solve the problem that the domestic spindle noise big, to ensure that customers using our company form a complete set of high speed braiding machine parts can significantly reduce the high speed braiding machine noise problems, ensure the customer equipment noise in the domestic leading position!

2 new material, made of injection plastic mould processing and development of knowledgeable of the industry should just tell us the company's spring spindle is new material production is not a product of the market above mixed a lot of back material, makes the product more strength and better toughness, better cold tolerance.Also we use the green color is the export of female customers can rest assured to environmental demanding the eu or Japan!

3 increase wear resistance of iron on the cover gasket Injection plunger into the general is not easy to pay attention to the opposite of, positive do frosted surface treatment External appearance more beautiful!

4 cover spring the heat treatment of 65 mn, is a stamping forming, no flash burr of molded parts, work not scrape yarn!All of the hardware Are fine production, and market of normal product has obvious difference!

Five line of spindle hook, we use the special assembly process, make the cladding ceramic at around 90%, close to the whole round, do not use glue adhesion.Ceramics with high strength and high wear resistance of white ceramic 99, make sure customers to use ceramic will not occur in the process of loss and fragmentation phenomenon.

6 on the spindle's ceramics are after a long fine polishing processing, and domestic market competing goods obvious smooth state Progress more smoothly.

7 overall do surface grinding processing, have qualitative feeling more, a large number of users can be customized special LOGO!

.jpg)