Mechanical nickel ore grab for sticky materials

| Min. Order: | 4 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 400pcs/year |

| Place of Origin: | Chongqing |

Company Profile

| Location: | Chongqing, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Tamping Rammer, Power Trowel |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Production Capacity: | 400pcs/year |

| Packing: | naked |

| Delivery Date: | 2 months |

Product Description

Some materials can be easy to grab but very difficult to unload because the material sticks to the grab.

Nickel ore and bentonite (when moist) are examples of this. Especially for sticky materials Verstegen

developed a grab with an adjusted "smooth scale design" and with special liners with an extreme low

friction coefficient. As a result even the stickiest materials will easily slide out of the grab scales

1in the ship crane, in the status of loading hooper.

Advantage

No stacking angle of dead. Bucket structure as open design, no stacking angle of dead.

No need clean bucket, Will not squeeze material on the process ,So nickel ore is loose and massive , All material will fall down clearly and easy when unloading. Nothing paste inside bucket.

No need close bucket when return to ship, As all material drop cleanly ,So no need close bucket when return ship.

No pollution and loss , No materials will drop to the dock and sea, In case pollution and the loss can be controlled.

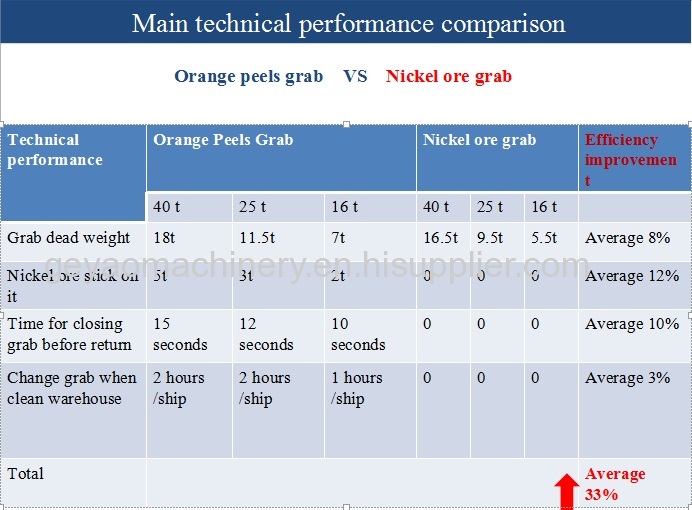

Smaller dead weight

The dead weight similar to other clamshell grab .Compared with orange peels ,this grab is much light weight, and handle more material .

Problems of other grabs previously

Low work efficiency

The nickel is viscous bulk including bauxite, clay which is serious sticky . Other grabs process make extrusion of material ,so always need to be clean inner bucket when unloading.

Pollution and loss

Others grab need close bucket peels before return to ship for next working circle,Otherwise lead leakage phenomenon and loss.