.jpg)

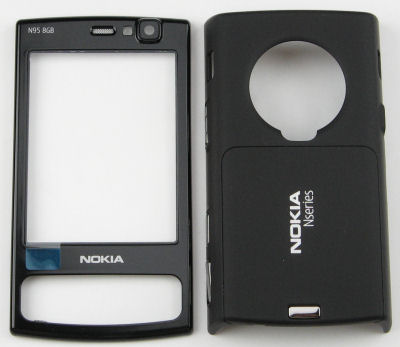

Mobile Phone Housing

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Brand Name: | Royalwill |

|---|---|

| Export Area: | global |

Product Description

Royalwill has its advanced CAD/CAM/CAE system and great team-workers experienced in mold design, manufacture and company management. And we are also familiar with mold manufacturing standards from

In addition to using steel P20 from

Royalwill is a professional ISO9001 certified plastic injection company and mould maker with more than ten years experience. We specialize in the design and manufacture of injection moulds and precision moulding/ production of plastic parts. We have state-of-art mould-making machinery, plastic injection moulding machines and over 400 skilled and dedicated workforces. Every year, over 70% of our moulds are exported to the

Our price is very competitive!

Plasticizing Capacity

The maximum amount of plastic required to fill the mold, including sprue, runner system, and cavities, must be less than 60 to 70% of the shot capacity of the molding machine to ensure proper plasticizing of the raw plastic material. Then, a judgement has to be made aboutwhether the dimensional tolerances of the product will allow multicavity molding within the quality limits imposed by the customer. Many customers now are demanding statistical quality control methods, which call for product to be dimensionally produced with three sigma limits falling within 70% of the tolerance zone.

.jpg)

.jpg)