Automatic Vaccum Screw Feeding Systems For Making Bottles Plastic Containers Buckets

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Automatic Blow Molding Machine, Bottle Blow Molding Machine, Extrusion Blow Molding Machine |

Product Detail

| Model No.: | BT |

|---|

Product Description

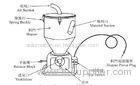

Automatic Vaccum Screw Feeding Systems For Making Bottles Plastic Containers Buckets

1. Host machine separated from the hopper, easy and safe to operate;

2. Independent filter for easy cleaning;

3. Stainless hopper;

4. Microcomputer controlled;

5. Alarm for overload and lack of material;

6. High-speed rectifier motor of small footprint and strong suction force for plastic material hopper loader

plastic material hopper loader

new material for NAL-700G

7. Induction high pressure pump of low noise and long service time for NAL-800G and

NAL-800G2; 8. Reverse cleaning for NAL-800G and NAL-800G2.

9. Separate control box for easy maintenance;

10. Auto-buzzer will give alarm when lacking material;

11. Auto-protection device protects motor against overloading;

12. Standard voltage: 380V 50Hz 3 Phase(optional);

|

Model |

Motor Spec. |

Enable for transtrip(kg/hr) |

Capacity |

DIA of pipe(mm) |

Measure(mm) |

Weight(kg) |

|

|

300S |

1KW 1Φ |

200 |

6L |

Φ38 |

340x340x590 |

13 |

|

|

400S |

0.75KW/1HP 3Φ |

250 |

6L |

Φ38 |

450x370x660 |

27 |

|

|

700G |

1.2KW 1Φ |

300 |

6L |

Φ38 |

560*370*290 |

14 |

|

|

|

|||||||

|

800G |

0.75KW 3Φ |

350 |

6L |

Φ38 |

430*360*260 |

47 |

|

|

|

|||||||

|

800G2 |

2HP 3Φ |

550 |

12L |

Φ38 |

660*420*370 |

66 |

|

|

|

|||||||

|

900G |

1HP/3Φ |

450 |

2*6L |

Φ38 |

375*710*680 |

64 |

|

|

900G2 |

2HP/3Φ |

700 |

2*12L |

Φ38 |

375*710*680 |

76 |

|

|

800G5 |

5HP/3Φ |

800 |

1*15L |

Φ38 |

970X640X480 |

80 |

|

Pakaging

1. Our EBM machines are designed with suitable dimension to fit a container inner loading size, every foot is locked with 8mm wire loop and special hook to the pothook of container to avoid moving in transportation.

2. The naked metal surface is greased