High Accuracy led Pick and Place equipment SMT Place Machine Surface Mounting

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 300set/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | SMT Machines |

Product Detail

| Model No.: | TM245P(Standard) |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | NeoDen |

| Contact: | tonny @ neodentech.com |

| Website: | http://www.neodentech.com/ |

| Applicable Components: | 0402-5050,ICs,TQFP,SSOP |

| Color: | Silver+Black |

| Max Speed: | 10000CPH |

| Position Accuracy: | ±0.03 |

| Feeders: | 27 |

| Tray ICs: | 5 Kinds |

| Max Mounting Size: | 370*450mm |

| Skype: | tonny-neoden |

| Production Capacity: | 300set/Month |

| Packing: | Wooden Case |

| Delivery Date: | 5 working days |

Product Description

TM245P(Standard Version)

1.Product Introduction

The third generation model TM245P is NeoDen Tech's independent product,with completely independent intellectual property,leading this technology in China.

TM245P series is the third generation of Neoden Tech's desktop pick and place machine,with high speed and accuracy,compact in boby,low power,stable performance and easy operation.Compared with the previous couple generation models TM220A and TM240A,TM245P series adopted automatic discharging device with electronic magnetic pressure type gear,vibration feeder which can support to mount components packaged by tubes,research and develop a new generation high speed drive system (equivalent to servo system),adding a new function of IC's mechanical correction and flexible PCB positioning function,committed to create the greatest value for customers in the actual production.

2.Characters:

The NeoDen third generation desktop pick and place machine TM245P is a model with completely independent intellectual property, which adopted the latest research and development of technology. Below are the new features of TM245P compare to the second-generation models TM220A and TM240A:

1. Automatic discharging device with electronic magnetic pressure type gear

2. Vibration feeder that can support to mount components packaged by tubes(Advanced Model equipped)

3. Developed a new generation high-speed drive system (equivalent to servo system)

4. Mechanical correction for IC mounting

5. Automatic recover function of step out

6. Flexible PCB positioning function

3.Parameters:

TM245P (Standard)

Max Mounting Size(X×Y) | 370*450MM(X*Y) |

Placement Head Q'ty | 2 |

Feeders | 27(standard left side feeder),customized back side feeder-Chargeable |

ICs | 10 |

Vibration feeder | No(Add should be chargeable) |

Max Mounting Capability | 10000CPH |

Position Accuracy | ±0.03 |

Max Movement speed | 2M/S |

Applicable component | 0402-5050,SOP,TQFP and etc,tape with(8mm,12mm,16mm and 24mm),the height under 5mm |

Max Applicable Height | 5mm |

External Dimension(L×W×H) | 870×640×336mm |

Negative Pressure | -92KPA |

Vacuum Pump Q'ty | 3 |

Power Supply | 220V/160W(Convertible to 110V) |

Net Weight | 45KG |

Fine-pitch IC correctional device: simple structure, used for mechanical correction of fine-pitch IC to ensure the mounting accuracy.

Automatic discharging device with electronic magnetic pressure type gear: patented, each unit is relatively independent and without interference, can peel the wasted nylon film more stable and easier.

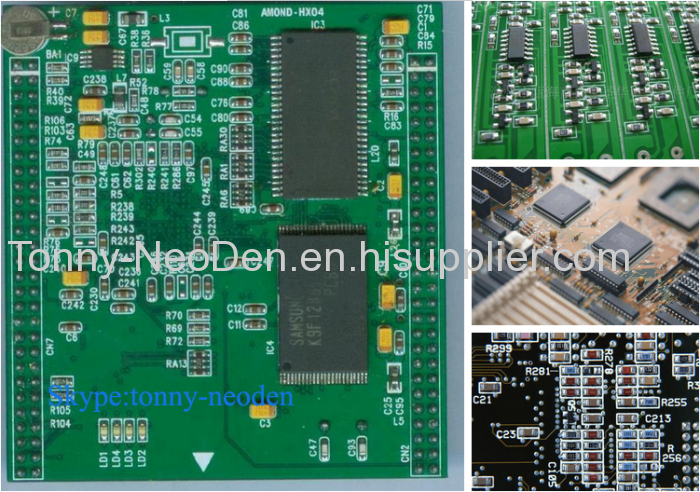

4.Mounting Effect:

5.Packing:

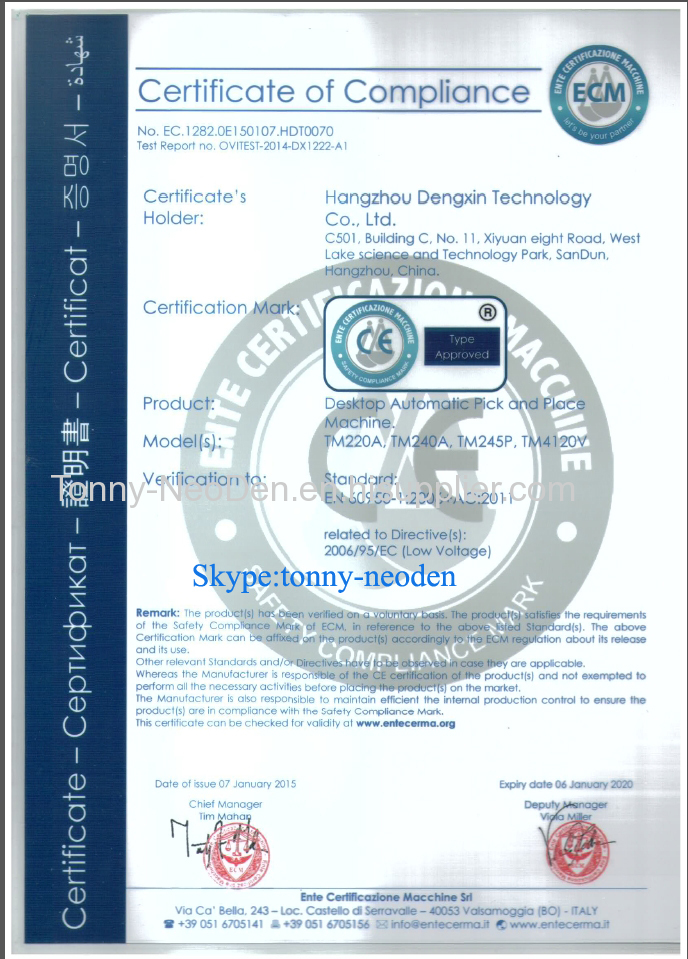

6.CE Certificate:

7.Standard Accessories for TM245P(Standard):

1) Pick and Place Machine TM245P: 1

2) Nozzle: Totally 10(XS:3 S:3 M:2 ML:2)

3) 8G SD Card: 1

4) Card reader: 1

5) Nozzle disassemble tool: 4

6) Power Cord: 1

7) Nozzle cleaning tool: 3

8) Open-end Wrench: 1

9) Video training course: 1

10) Double Sides Adhesive Tape: 2

11)Wrench Set:7

12)Tool Box:1

13)External Shelf:1

14)Positioning Strip:4

15)Positioning Column:8

16)Needle:4

17)Electromagnet:2

18)Electromagnetic Valve:4

19)Silicone Pad:8

20)Module's Rear Cover:1

21)Voice Coil Motor 8mm:4

22)Voice Coil Motor 12mm:2

23)Voice Coil Motor 16mm:1

Warranty:

The complete machine has a warranty period of TWO year from the time of purchase and lifelong service support as well as a long-term factory price supply. We provide online Q/A and troubleshooting support and technical advice service.

Thank you very much for your support on Hangzhou NeoDen Technology's products.

Email:Tonny @ neodentech.com Skype:tonny-neoden