Desktop Prototype Pick and Place machine from NeoDen Tech

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 300set/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | SMT Machines |

Product Detail

| Model No.: | TM220A |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | NeoDen Tech |

| Contact: | tonny @ neodentech.com |

| Color: | Silver |

| Power Supply: | 220V 50Hz (Convertible to 110V) |

| New/Old: | New |

| Manufacturer: | NeoDen Tech |

| Max Applicable PCB: | 220mm*200mm |

| Max Speed: | 7000PCS/h |

| Positioning accuracy: | ±0.025mm |

| Average working power: | 1010W |

| Feeders: | 16 Pcs |

| Production Capacity: | 300set/Month |

| Packing: | Wooden Case |

| Delivery Date: | 5 working days |

Product Description

NeoDen TM220A and NeoDen TM240A are desktop automatic pick and place machines especially developed for research laboratories and small medium manufacturing enterprises however it will also be suitable for the serious hobbyist.These automatic pick and place machines are suitable for small batch production, laboratory research and development, product sample trials, LED SMT processing and other similar processes.

Technical Parameters | |

Version | TM220A |

Applicable PCB | 20mm*20mm~220mm*200mm |

Placement head quantity | 2 |

Max mounting capability | 7000PCS/h |

Positioning accuracy | ±0.025mm |

Applicable Components | 0402-5050,SOP, QFN, IC |

Components supply configuration | Tape reel, bulk package (IC) |

Tape width | 8mm, 12mm, 16mm |

Feeders | 16 (8mm=12, 12mm=2, 16mm=1, bulk IC=1) |

External Dimension | L 830mm×W 455mm×H 285mm |

Vacuum pump | -92KPA (Mute type pump) |

Vacuum pump quantity | 2 (Built-in) |

Power supply | 220V, 50Hz (Convertible to 110V) |

Average working power | 100W |

Weight | G.W: 45KG (N.W: 25KG) |

Packing size | L 101cm×W 61cm×H 48cm |

Product Characteristic:

1) The machine have both Chinese and English version, which would be very user friendly for our foreign customers.

2) Coverfoil automated peel away device: Very convenient, and could make sure coverfoil peel away smoothly and without jerking from the tape, which could effectively prevent components jump out of the tape and jam the machine.

3) With 2 placement heads: 2 components could be picked and placed at the same time at every working stroke of the machine.

4) Could place components on the correct footprints with 360 degree orientation, and with required precision.

5) Automatic vacuum detection function, which could automatically recognize missing components, and remind user timely.

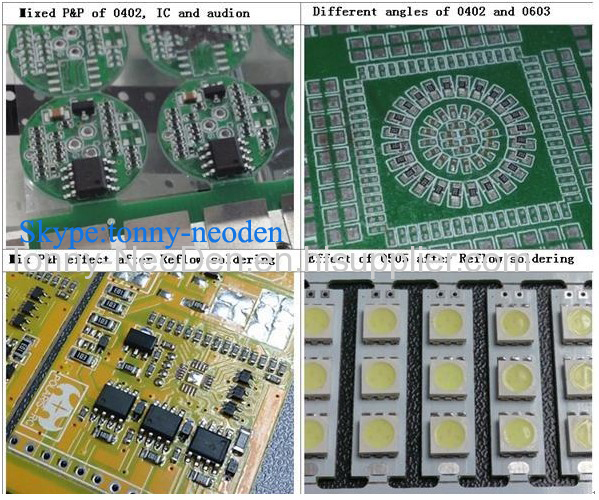

6) Could handle the mounting for 0402 and IC components with required precision, even without vision system. The self-developed Laser positioning principle is quite effective for this type of machine.

7) Self developed Software operating system which is integral to the machine, no need to (and can not) attach to a separate computer. 8G SD Card would be big enough for you to setup hundred thousands files.

8) Integrated type of feeders: No need to buy extra mobile feeder arrays, which is quite cost saving.

9) Feeders are mechanized to automatically present the next component after the preceding one has been collected.

10) Easy and storability of programming, and high speed of changeover from one placement program to another.

11) The programming process is very simple and quick: use Protel tool to extract the PCB circuit coordinate file, and use the format transformation tool we provided to you to transform the file format, and then copy to the SD card, insert to the machine, then you could use the file directly.

12) Online programming function: could easily online programming if you don't have PCB Circuit diagram.

13) Small and lightweight: simple installation, convenient transportation.

14)Working power 100W: Environmental protection and energy saving.

Video Shows:

https://www.youtube.com/channel/UCe5FjacDVT42MxKF2Q6Z9OQ/videos?view=0&sort=dd&shelf_id=0

Mounting Effect:

Standard Accessories:

1) Pick and Place Machine TM220A: 1

2) 4 types of nozzle: Totally 6 (XS—2, S—2, M—1, ML—1).

3) 8G SD Card: 1

4) Card reader: 1

5) Nozzle disassembly tool: 1set

6) Adjustment tool for Nylon Spool Wheel: 1

7) Nozzle cleaning tool: 1 set

8) User manual: 1

9) Video training course: 1 set

10) PCB Coordinate file transformation tool: 1

Export Stand Package:

Warranty:

The complete machine has a warranty period of one year from the time of purchase and lifelong service support as well as a long-term factory price supply. We provide online Q/A and troubleshooting support and technical advice service.

Thank you for your kindly support.

You can also contact me with email:

Tonny @ neodentech. com

Skype:tonny-neoden