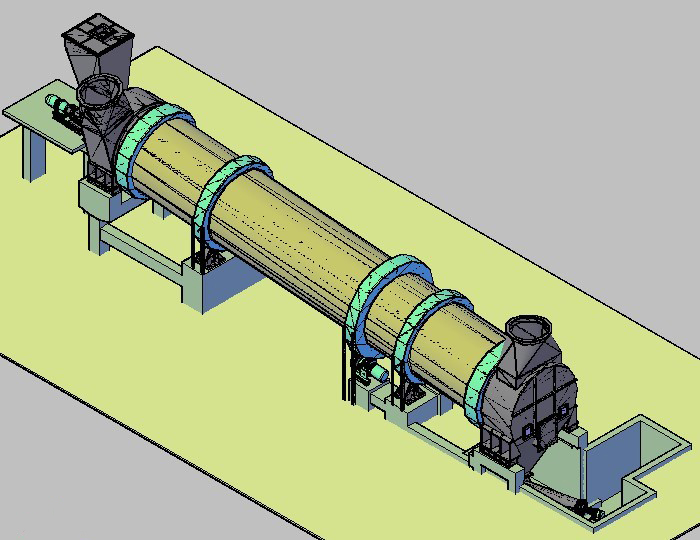

Pig Manure Dryer Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ball Mill, Jaw Crusher, Impact Crusher, Sand Washer, Drying Machine |

Product Detail

| Model No.: | ZT-3.6*25 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Others |

| Type: | Others |

| Brand Name: | zhongke |

| Inside diameter(m): | 3.6 |

| Length(m): | 25 |

| Gradient(%): | 4.0 |

| Rotate speed(r/min): | 2.7 |

| Power(kw): | 132 |

| Capacity(t/h): | 95-110 |

| Weight: | 188 |

| Warranty: | 1 year |

| Certification: | ISO 9001:2008 |

| Condition: | New |

| Production Capacity: | 10 sets/month |

| Packing: | Standard international export packing, container, or as the requirement |

| Delivery Date: | 15-20 days after receiving the prepayment |

Product Description

Application of Pig Manure Drying

The Pig Manure Dryer can dry various materials, such as wood materials, fiber materials, sand type materials, powder type materials, and even block type materials in many fields. It has the advantages of reasonable structure, little wearing parts, large capcity, low energy consumption, convenient to operate

Working Principle of the Pig Manure Dryer:

Materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator.The barrel is installed with slope to horizontal line. Materials enter the barrel from the higher side, and hot air enters the barrel from the lower side, materials and hot air mix together. Materials go to the lower side by gravity when the barrel rotates. Lifters on the inner side of barrel lift materials up and down to make materials and hot air mix completely. So drying efficiency is improved.

1.This drying machine consists of rotary body, material plate, conveying device, supportive device, sealing ring and other components.

2.Since the machine has a gradient, the materials enter the cylinder from its higher side. There is full of hot gas in the cylinder, materials will be rolled by the metal plate inside up and down to accelerate the drying rate, then they will pushed to the lower side by the rolling device. The dried materials will be collected at the bottom.

Features:

1 the rotor with high mechanization, larger production capacity, continuous operation.

2 simple and good structure, with smooth operation when material get through the cylinder.

3 low malfunction, low maintenance cost, low power consumption.

4 widely used, good uniformity for the dried products.

5 not only for dry ,but for sterilization and deodorization.

Main Technical parameters

Model | Inside Dia. | Length | Gradient | Rotate Speed | Power | Capacity | Weight |

ZT-1.2X6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

ZT-1.5X12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

ZT-1.8X12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/2100 |

ZT-2.2X12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

ZT-2.4X14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

ZT-2.4X18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

ZT-2.4X22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

ZT-2.8X20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

ZT-3.0X22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

ZT-3.2X25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

ZT-3.6X25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

About us:

Henan Zhongke Engineering & Technology Co., Ltd. since its inception has been to customers to provide quality and efficient service. Production jaw crusher, counter type crusher, hammer crusher, vibrating screen set of sand production line, aeratedconcrete equipment deep customer satisfaction. Our caring service, careful manufacture, price satisfaction, let customer feel rest assured . "Customer oriented", provide overall service for the customer; "to serve as the core", for customers to create the most valuable products. "Take the quality as the center", a full range of services to customers.