Wood chip drier equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ball Mill, Jaw Crusher, Impact Crusher, Sand Washer, Drying Machine |

Product Detail

| Model No.: | ZT-3.0*22/25 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Others |

| Type: | Others |

| Brand Name: | zhongke |

| Inside diameter(m): | 3.0 |

| Length(m): | 22/25 |

| Gradient(%): | 4.0 |

| Rotate speed(r/min): | 3.2 |

| Power(kw): | 75 |

| Capacity(t/h): | 58-70 |

| Weight: | 88/95 |

| Warranty: | 1 year |

| Certification: | ISO 9001:2008 |

| Condition: | New |

| Production Capacity: | 10 sets/month |

| Packing: | Standard international export packing, container, or as the requirement |

| Delivery Date: | 15-20 days after receiving the prepayment |

Product Description

Introduction

Wood chip drier is also known as drying wood chip machine, wood shavings dryer or wood chip drying machine. Wood chip dryer is designed for wood chips, sawdust, sawdust, wood chips and other materials. Wood shavings dryer has the characteristics like large capacity, remarkable energy saving, low maintenance and so on. And the main working principle is the wood chips go into wood chip dryer or and woodchip dryer under the effect of injection tube and rotating cylinder effects, the materials boil and fluidify in the cylinder. The hot-blast makes full contact with the material to complete drying.

Principle

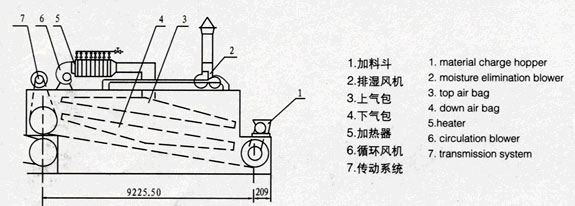

Wood chip dryer is mainly composed of air heaters, feeding machine, air flow drying tube, cyclone separator, and draught fan. Air drying is the method that the wood chip is conveyed into the drying tube by the spiral conveyor constantly. Through the transmission and dispersion of hot air flow, the moisture in the materials will be evaporated.

Features

1. High productivity.

2. Energy saving and pollution free.

3. Long life expectancy.

4. Costs saving.

Installation Method of Wood Chip Dryer:

1. Wood shavings dryer should be installed on a horizontal concrete foundation, using anchor bolts.

2. Pay attention to the host body perpendicular to the level.

3. After the installation, check for whether there are loose parts bolted or host doors are fastened,

4. Supply line and the control switch according to device's power.

5. After finish checking, conduct no load test. If test is qualified, the wood chip dryer can be used to make production.

Main Technical parameters

Model | Inside Dia. | Length | Gradient | Rotate Speed | Power | Capacity | Weight |

ZT-1.2X6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

ZT-1.5X12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

ZT-1.8X12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/2100 |

ZT-2.2X12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

ZT-2.4X14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

ZT-2.4X18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

ZT-2.4X22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

ZT-2.8X20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

ZT-3.0X22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

ZT-3.2X25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

ZT-3.6X25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

About us:

Henan Zhongke Engineering & Technology Co., Ltd. since its inception has been to customers to provide quality and efficient service. Production jaw crusher, counter type crusher, hammer crusher, vibrating screen set of sand production line, aeratedconcrete equipment deep customer satisfaction. Our caring service, careful manufacture, price satisfaction, let customer feel rest assured . "Customer oriented", provide overall service for the customer; "to serve as the core", for customers to create the most valuable products. "Take the quality as the center", a full range of services to customers.