Compound fertilizer dryer machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ball Mill, Jaw Crusher, Impact Crusher, Sand Washer, Drying Machine |

Product Detail

| Model No.: | ZT-2.8*20 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Others |

| Type: | Others |

| Brand Name: | zhongke |

| Inside diameter(m): | 2.8 |

| Length(m): | 20 |

| Gradient(%): | 4.0 |

| Rotate speed(r/min): | 3.7 |

| Power(kw): | 40 |

| Capacity(t/h): | 45-55 |

| Weight: | 71/75 |

| Warranty: | 1 year |

| Certification: | ISO 9001:2008 |

| Condition: | New |

| Production Capacity: | 10 sets/month |

| Packing: | Standard international export packing, container, or as the requirement |

| Delivery Date: | 15-20 days after receiving the prepayment |

Product Description

Introduction

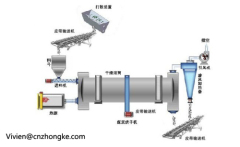

Compound fertilizer dryer is also known as drum dryer, used for drying climate and granular fertilizers, while can also be used for drying other materials. The distribution and angle of the lifting plate is reasonably designed, with reliable performance, thus compound fertilizer drying machine has advantages of high thermal energy utilization, uniform drying, less number of times to clean material, convenient maintenance and so on. Compound fertilizer dryer is mainly used in the production of organic compound and compound fertilizer.

Principle

Compound fertilizer dryer is fed on the stock guide of compound fertilizer dryer via chute, along with the rotating of barrel, compound fertilizer will be led to inclined lifting plate lifted up to central location of dryer tube, and then gradually fell down like a curtain, so the high temperature air flowing through it can preheat and evaporate moisture in materials. When the compound fertilizer fell down and spilled on grate-wing, the material will be mixed together with preheated grate plate wing, so that part of water in material can be evaporated. At the same time, wings entrained materials lift and fall many times, for materials fully contact with hot air convection and heat exchange. Along with the rotating of cylinder, part water in material can be evaporated, and compound fertilizer can be further dried. Finally, the dried compound fertilizer with low moisture content is loose material and be discharged through discharge port.

Features

1. Compound fertilizer dryer has high mechanical degree and large production capacity, and continuous operation is OK.

2. Compound fertilizer drying machine has simple structure, smooth running when materials pass through the cylinder, and ease operation.

3. Compound fertilizer dryer has less troubles, low maintenance cost and low power consumption.

4. Compound fertilizer drying machine has wide application, and good uniformity of product drying.

5. Compound fertilizer dryer machine can achieve the purpose of sterilization and deodorization while drying materials.

Main Technical parameters

Model | Inside Dia. | Length | Gradient | Rotate Speed | Power | Capacity | Weight |

ZT-1.2X6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

ZT-1.5X12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

ZT-1.8X12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/2100 |

ZT-2.2X12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

ZT-2.4X14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

ZT-2.4X18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

ZT-2.4X22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

ZT-2.8X20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

ZT-3.0X22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

ZT-3.2X25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

ZT-3.6X25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

About us:

Henan Zhongke Engineering & Technology Co., Ltd. since its inception has been to customers to provide quality and efficient service. Production jaw crusher, counter type crusher, hammer crusher, vibrating screen set of sand production line, aeratedconcrete equipment deep customer satisfaction. Our caring service, careful manufacture, price satisfaction, let customer feel rest assured . "Customer oriented", provide overall service for the customer; "to serve as the core", for customers to create the most valuable products. "Take the quality as the center", a full range of services to customers.