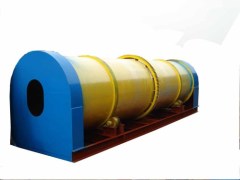

Chicken manure dryer equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ball Mill, Jaw Crusher, Impact Crusher, Sand Washer, Drying Machine |

Product Detail

| Model No.: | ZT-2.8*20 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Others |

| Type: | Others |

| Brand Name: | zhongke |

| Rotate speed(r/min): | 3.7 |

| Power(kw): | 40 |

| Capacity(t/h): | 45-55 |

| Gradient(%): | 4.0 |

| Voltage: | 380V |

| Weight: | 71/75 |

| Warranty: | 1 year |

| Certification: | ISO 9001:2008 |

| Condition: | New |

| Place of Origin: | Henan, China (Mainland) |

| Production Capacity: | 10 sets/month |

| Packing: | Standard international export packing, container, or as the requirement |

| Delivery Date: | 15-20 days after receiving the prepayment |

Product Description

Features of Chicken manure dryer:

1.Chicken manure dryer is a low-fuel-consumption and high efficiency of drying equipment. Can be used to dry the material with a moisture content below 85% to a final moisture content below 13%. Applicable in animal farming, food brewing, sugar and pharmaceutical industries dealing with high humidity waste, as well as a variety of chemical raw materials, such as chicken manure, wine slot, furnace slag, fructose slag, slag vinegar sauce, sugar beet residue, animals slaughtered contents, coal slime, bentonite, and more.

2.For resource development and good environmental protection equipment. The equipment uses downstream drying process, especially suitable for fast drying the humidity materials which need to preserve nutrition, for example, the drying of fresh chicken manure can achieve the purposes of drying, sterilization, deodorant and preservation of nutritional.

3.Equipped with high-speed rotating drum of crushing devices, which increases the contact area between material and drying medium, the internal unique equipment design, makes materials difficult to adhere to the drum wall panels and parade.

4.The complete machine has the effects of heat preservation, good sealing performance, and the fact that the thermal efficiency considerably higher than the general drum dryer

5.The dryer structure is compact, easy to install and debug, and using small floor area.

6. Drum and crushing device use stepless speed regulating devices, which can adapt to the different requirements of the drying materials.

7.The dryer can combine the use of different fuels (such as coal, heavy oil, natural gas, and more).

Working Principle of Chicken Manure Dryer:

The complete sets of equipment mainly is composed of the crushing drum dryer, burning furnace, feed spiral, output spiral, pipeline, dust collector, airlock, air induced fan, electric control cabinet and other components.Humidity materials are conveyed from the feed screw directly into the dryer drum, raised by the drum wall panels repeatedly, and scattered by the crushing blow dispersion devices. Materials and the negative high-temp media are combined sufficiently to complete heat and mass transfer process. As the result of the drum wind angle and the induced air, the feed materials move slowly, and discharged from the spiral after drying, the exhaust gas handled by the dust precipitator, venting to the atmosphere.

High density rotary dryer parameters

Model | Inside Dia. | Length | Gradient | Rotate Speed | Power | Capacity | Weight |

ZT-1.2X6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

ZT-1.5X12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

ZT-1.8X12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/2100 |

ZT-2.2X12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

ZT-2.4X14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

ZT-2.4X18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

ZT-2.4X22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

ZT-2.8X20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

ZT-3.0X22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

ZT-3.2X25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

ZT-3.6X25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

About us:

Henan Zhongke Engineering & Technology Co., Ltd. since its inception has been to customers to provide quality and efficient service. Production jaw crusher, counter type crusher, hammer crusher, vibrating screen set of sand production line, aeratedconcrete equipment deep customer satisfaction. Our caring service, careful manufacture, price satisfaction, let customer feel rest assured . "Customer oriented", provide overall service for the customer; "to serve as the core", for customers to create the most valuable products. "Take the quality as the center", a full range of services to customers.