Lignite dryer machine manufacturer

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ball Mill, Jaw Crusher, Impact Crusher, Sand Washer, Drying Machine |

Product Detail

| Model No.: | ZT-2.2*12/14 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Coal |

| Type: | Others |

| Brand Name: | zhongke |

| Rotate speed(r/min): | 4.3 |

| Power(kw): | 22 |

| Capacity(t/h): | 22-28 |

| Gradient(%): | 5.0 |

| Voltage: | 380V |

| Weight: | 37.1/38.8 |

| Warranty: | 1 year |

| Certification: | ISO 9001:2008 |

| Condition: | New |

| Place of Origin: | Henan, China (Mainland) |

| Production Capacity: | 10 sets/month |

| Packing: | Standard international export packing, container, or as the requirement |

| Delivery Date: | 15-20 days after receiving the prepayment |

Product Description

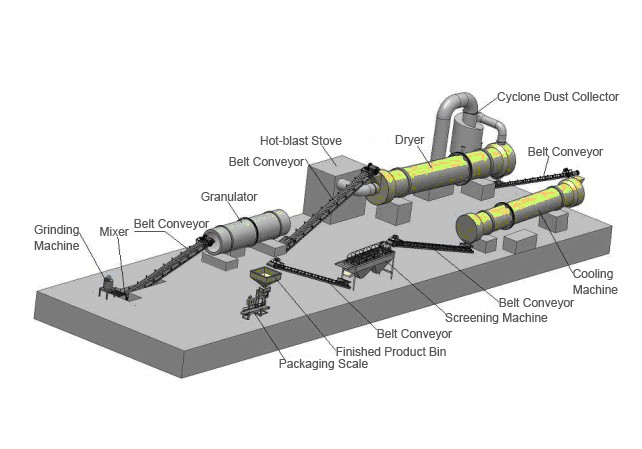

Under the unchanged condition of the quality of dried lignite, lignite dryer adopts low temperature four class drying process to make the moisture content of lignite evaporated below 13%.

Lignite coal dryer, also known as lignite rotary dryer, brown coal dryer, lignite dryer or coal ash dryer, is suitable for granular materials and can also be partially put into dry adhesive materials, pasty materials or high water content materials. Lignite coal dryer is widely used in the drying of materials in cement, mining, building materials, chemical, food, fertilizer production industry, etc.

Principle

Lignite, coal ash and other material are sent into feeder through conveyor belt, and the coal ash is sent into drying roller through the feeder. With the ruffle of uniformly distributed board device in drying roller, the coal ash is evenly contacted with hot air to transfer heat and perfect drying. The dried coal ash is discharged into finished products via shedder in the end of the roller. The dried products are discharged by the belt discharging machine, and the drying process is finished.

Special characteristics of Lignite dryer:

Environmental protection, energy and reducing loss of lignite.

Improve the calorific value of brown coal, desulfurization, and reduce volatile.

Investment, small footprint, and supporting civil works less.

Reliable, simple operation, convenient maintenance, safe and durable.

Dry and moisture control, minimum up to 5% or less, meet the material widely.

Even temperature drying process to ensure the quality of lignite change.

Continuous work and large capacity.

Lignite dryer market outlook of Lignite dryer:

With implementation of the strategy of sustainable development, coal and other mineral resources, the rational development and utilization has become an important issue, the original low value the full development and utilization of lignite is urgent. Use of valuable lignite resources, so that turning waste into wealth, not only can produce considerable economic benefits. lignite dryer, can be dry and brown in ensuring the quality of the same premise, reducing the sulfur content of lignite to improve the calorific value of lignite.Improve combustion efficiency, making more full use of coal resources.

Applications include of Lignite dryer:

lignite, quality, dry municipal sludge, paper sludge, leather sludge, printing and dyeing sludge, chemical materials and pharmaceutical liquid fermentation residue, food fermentation, sugar residue, rosacea, chemical organic waste, and more

High density rotary dryer parameters

Model | Inside Dia. | Length | Gradient | Rotate Speed | Power | Capacity | Weight |

ZT-1.2X6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

ZT-1.5X12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

ZT-1.8X12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/2100 |

ZT-2.2X12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

ZT-2.4X14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

ZT-2.4X18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

ZT-2.4X22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

ZT-2.8X20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

ZT-3.0X22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

ZT-3.2X25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

ZT-3.6X25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

About us:

Henan Zhongke Engineering & Technology Co., Ltd. since its inception has been to customers to provide quality and efficient service. Production jaw crusher, counter type crusher, hammer crusher, vibrating screen set of sand production line, aeratedconcrete equipment deep customer satisfaction. Our caring service, careful manufacture, price satisfaction, let customer feel rest assured . "Customer oriented", provide overall service for the customer; "to serve as the core", for customers to create the most valuable products. "Take the quality as the center", a full range of services to customers.