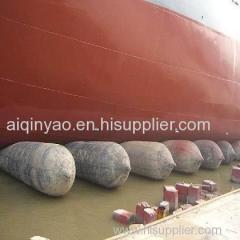

NANHAI NO.1Rubber Marineairbagsfor ship launching and upgrading

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Pneumatic Fender, Yokohama Fender, Ship Launching Airbag |

Product Detail

| Model No.: | 1 D X 12 L |

|---|

Product Description

NANHAI NO.1 marine airbags / rubber airbags for ship launching and upgrading

marine launching airbags characteristics:

1.Wear resistance and anti-aging:An airbag often works in extreme conditions, for example, it is soaked in sea water, insolated in the direct sunlight and rolled in sand.Our marine is produced with natural rubber in a reasonable formula.The practice proves that airbag has high wear resistance and anti-aging ability, and the service life as long as 8-10 years.

2.High strength:The polyamide cord thread for airbag is produced with high tension reinforced fiber.A cord thread has the strength more than 320N, and the cord fabric has consistent and reliable quality.

3.Good air tightness:Our Company use high quality rubber, as material and the advanced manufacture process to assure that our products have good air tightness, especially air tightness of the assisted floated airbag.Our airbag can keep its pressure 24 hours with work pressure, the pressure will reduce less than 3%.

4.Safety and reliability:Giyo marine airbag with the optimized structure design has the safety coefficient of 4-6 times, namely that its bursting pressure is 4-6 times its work pressure.Our airbag has a multi-channel airbag mouth to enhance the strength and air tightness between the airbag body and mouth.

Marine Airbag Specifications:

Good selection of marine airbags is vital for the success of marine projects. Get basic knowledge of marine airbags selection then consult with manufacturers can help people complete projects in shortest time.

|

Diameter |

Layer |

Work pressure |

Diameter |

Layer |

Work pressure |

|

D=0.8M |

3 |

0.13 Mpa |

D=1.5M |

3 |

0.07 Mpa |

|

4 |

0.17 Mpa |

4 |

0.09 Mpa |

||

|

5 |

0.21 Mpa |

5 |

0.11 Mpa |

||

|

6 |

0.25 Mpa |

6 |

0.13 Mpa |

||

|

7 |

0.30 Mpa |

7 |

0.15 Mpa |

||

|

8 |

0.33 Mpa |

8 |

0.18 Mpa |

||

|

D=1.0M |

3 |

0.10 Mpa |

D=1.8M |

3 |

0.06 Mpa |

|

4 |

0.13 Mpa |

4 |

0.08 Mpa |

||

|

5 |

0.17 Mpa |

5 |

0.09 Mpa |

||

|

6 |

0.20 Mpa |

6 |

0.11 Mpa |

||

|

7 |

0.25 Mpa |

7 |

0.13 Mpa |

||

|

8 |

0.28 Mpa |

8 |

0.15 Mpa |

||

|

D=1.2M |

3 |

0.09 Mpa |

D=2.0M |

3 |

0.05 Mpa |

|

4 |

0.11 Mpa |

4 |

0.07 Mpa |

||

|

5 |

0.14 Mpa |

5 |

0.08 Mpa |

||

|

6 |

0.17 Mpa |

6 |

0.10 Mpa |

||

|

7 |

0.20 Mpa |

7 |

0.12 Mpa |

||

|

8 |

0.23 Mpa |

8 |

0.14 Mpa |

Marine Airbag description

Marine airbags now are used for ship launching, loading and floating. They are widely used in cargo boat/ship/vessel launching and landing, lifting and moving sunken ships and salvaging stranded boats. Air bags have the benefit of not only saving labor and time, but investment costs. Additionally they are flexible portable and dependable.

The structure of Marine Airbag

The structure Nanhai No. 1 Marine airbag for ship is shown in Fig. 4. It consists of a bag body and end-iron component. The bag body is made from vulcanization of base rubber and reinforced fiber material. The end-iron component is made of metal materials and connected to the bag body firmly.

Our Marine Airbag

NANHAI AIRBAG Management system is ISO9001: 2000 certified and complys with all demands of the ISO 14409: 2011 standard ( For ship launching airbags) during manufacturing procedure . NANHAI AIRBAG guarantees excellent quality and performances of all products. Customer requirements are strictly followed during all production phases. His quality control department performs a true procedure control of the material and products.