Popular Safe Plate Pressure Oil Filter

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 2000sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Food Machinery, Meat Machine.egg Machine, Oil Expeller |

Product Detail

| Model No.: | 6LB-250 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Processing Types: | Edible Oil |

| Processing: | Others |

| Brand Name: | ALLANCE |

| Material: | staineless steel |

| Power: | 0.75 Kw |

| Dimension: | 900*550*770mm |

| Output: | 100Kg/h |

| Weight: | 170kg |

| Production Capacity: | 2000sets/month |

| Packing: | plywood case |

| Delivery Date: | 10-15 days after deposit receipt |

Product Description

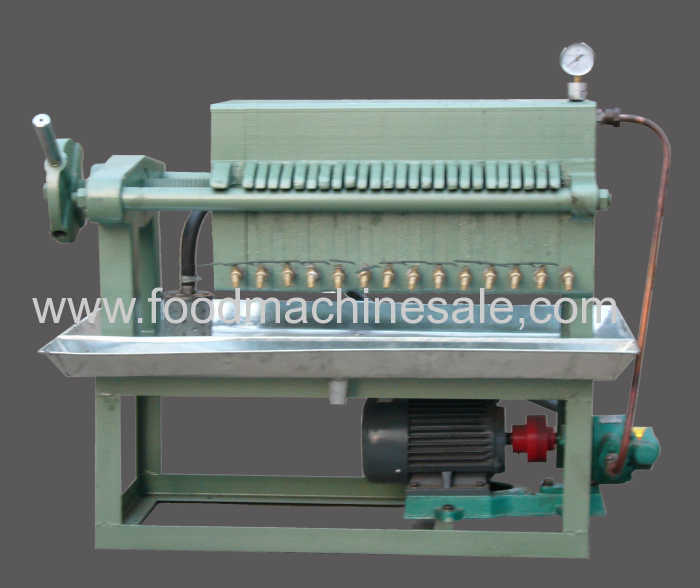

Plate Pressure Oil Filter Instruction

Plate pressure oil filter is mainly designed to separate the tiny impurities and moisture from oil, thus can improve the oil quality and economic value. It can be used with the oil press. It's characterized by simple structure, easy operation and low cost etc. Plate Pressure Oil Filter Features

Plate Pressure Oil Filter Features

◆Reasonable design, attractive appearance, compact structure, easy and convenient operation.

◆The pressure, temperature and liquid level has clear data indication and automatic control device, safe and reliable.

◆The filter is with high filtration speed and the filtered oil is of high quality — no froth, less oily fume and no sediment.

Plate Pressure Oil Filter Structure

Plate pressure oil filter is composed of filter bed, oil pump and primary filter etc. There is filter cloth between the filter plate and filter frame as filter medium. The filter plate and filter frame can form a single filter chamber rely on the pressure of depress device. The filter paper or filter cloth which compressed by the filter plate and filter frame can separate the oil and residue of the crude oil.

Plate Oil Filter Operation Working Principle

1. Press the hole-punched filter papers between each filter plate and filter frame before operation. Each layer places one or two filter papers according to the filter requirement and filter paper quality.

2. The filter paper should be dried before using with drying temperature around 120℃.

3. If use the used filter paper, the paper should be stoved. The side with residues should face the filter frame to avoid the residues flowing into the filtered oil.

4. If the filter pressure is higher and the filter paper is broken, you can place filter cloth close to the filter plate side to increase the filtration strength.

.jpg)

.jpg)