Automatic Forklift Powder Paint Equipment

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20pcs/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | FF-LF |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Feifu |

| Certification: | CE ISO |

| Application: | Electrostatic Powder Coating |

| Voltage: | 380V |

| Model: | FF-LF |

| Dimension(L*W*H): | According to factory size |

| Warranty: | 12 Months |

| Motor fan power: | 5.5kw |

| Compressor+air storage tank: | 1 set |

| Chamber body: | A3 plate t1.5mm |

| Production Capacity: | 20pcs/year |

| Packing: | wooden case or carton package |

| Delivery Date: | 30-60 days after payment |

Product Description

Automatic Forklift Powder Paint Equipment

Powder Coating Line adopts process including pre-cleaner, water drying, powder coating spray, curing on metal surface.

It shall be designed on the base of workpiece size, production output and occupied area.

Pre-cleaner: the base for the whole process. If the workpiece surface is well dealt with, the powder coating effect will be better.

Water Drying: The drying system is for drying the wet workpiece after pre-treatment, It is design according to different requirement. The temperature about 100 degree centigrade for 10-15 mins.

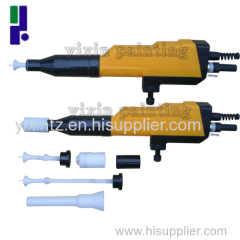

Powder Coating Spray: Powder Coating painting is usually processed in powder coating spray booth, with powder coating manual spray gun or automatic spray gun. If auto gun used, it usually connected with paint robot like following:

Curing on Metal Surface: Powder Curing Oven could make as tunnel curing oven and bridge powder curing oven. With temperature 180-200 degree centigrade for 15-20mins. Energy could be electric, natural gas, or diesel.

Some related products applied into powder coating production line: