Vertical coating system for aluminum profiles

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T, WU, Money Gram |

| Supply Ability: | 1PCS/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand name: | FeiFu |

| Line type: | vertical |

| product: | mental products |

| working voltage: | 220V/380 |

| Spray booth: | Stainless steel |

| warranty: | 1 year |

| Certification: | CE |

| Powder coating: | automatic |

| Series: | powder coating equipment line |

| GUN: | Corona spray gun |

| Production Capacity: | 1PCS/month |

| Packing: | container |

| Delivery Date: | 45-60days |

Product Description

Vertical coating system for aluminum profiles

Powder coating is a very durable method of providing a decorative finish to metals and a range of other materials.

Common market sectors include, Window systems, Conservatory sections, hinges, lighting systems, curtain track and rail, desking systems including office furniture.

Our powder coating facility offers finishing in a variety of colours with RAL,or colour matched powders. We are able to powder coat both aluminium and steel components.

Vertical aluminium powder coating line have more advantage such as:

High production

Fasta change color and more efficient.

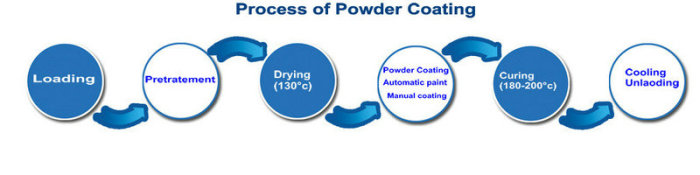

Powder Coating Aluminium – The Process

The powder coating process starts with the metal components being cleaned, which helps the coating to adhere to the metal.

This process is carried out in a multistage immersion water tank system as follows;

A de-greaser is used to clean the metal after which a two bath rinse cleans it down.

Finally a drying oven is used to ensure no moisture is present when the items are powder coated.

The components are then suspended and passed through a spray booth where the powder is applied by spray guns.

Once the powder has been applied it is passed through a curing oven where the particles melt and fuse together and adhere

to the components surface. This produces a uniform, smooth, durable finish.

Capalex use a automatic continuous chain/conveyor system.

Metal is loaded onto the hangars and then passed through the

spray guns / curing ovens/coolers.

This has a maximum length of 6000mm.

We also have the ability to do small runs and prototypes with a small secondary booth, with a maximum length of 2000mm.

Although we primarily coat aluminium extrusions, we can coat small aluminium components, steel brackets, steel components and larger steel items.

More details, please contact with us by emila o SKYPE.