Wood Sawdust Rice Husk Wheat Straw Bran Biomass Pellet Machine Price

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,CIP,CPT,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100 sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Pellet Machine, Pellet Mill, Pellet Line, Hammer Mill, Dryer |

Product Detail

| Model No.: | TYJ550 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product Name: | Biomass Vertical Ring DIe Pellet Mill |

| Raw Material: | Wood Sawdust,straw,rice husk,alfalfa,palm,bagasse,bamboo |

| Allication: | Biomfuel pellets making |

| Lubrication: | Automatic |

| Pellet Diameter: | 4-12mm |

| Driving method: | AC Electric |

| Vlotage: | 380V, 50Hz |

| Transmission Type: | Big Gear |

| Brand: | TONY |

| Service: | Engineer avaliable to service abroad |

| Production Capacity: | 100 sets/month |

| Packing: | wooden or iron case |

| Delivery Date: | 1-12 days |

Product Description

Requirement for raw materials for pellet machine

Raw material: wood, waste wood and straws, etc. such as woodchips(palm, pine white pine, mahogany, pinus sylvestris, rubber tree), bamboo shavings, rice hust, seeds shells, peanut shells, halm, pennisetum, wheat straw, corn stalk, cotton stalks, alfalfa grass, bagrass, palm fiber, waste paper, non-physical material

Size:1-5mm (All the raw materials must be crushed into sawdust before going

to wood pellet machine.If not, you may need a wood chipper, wood crusher.)

Moisture: Generally, 10-15% is best for producing good quality wood pellet.

Technical Datas of Ring Die Pellet machine with big gear

Model | Power(KW) | Capacity(T) | Weight(T) | Size(mm) | Remark |

TYJ450-II | 55 | 0.8-1.2 | 2 | 1350*850*1500 | Gear Transmission |

TYJ550-II | 110 | 1.5-2 | 4 | 1850*1050*1800 | |

TYJ680-II | 160 | 2-2.5 | 6 | 2150*1180*1950 | |

TYJ860-II | 220 | 2.5-3.5 | 8 | 2430*1380*2100 | |

TYJ980-II | 315 | 3.5-5 | 12 | 2800*1500*2500 |

Tech Datas of Pelle machine with reducer driver

Model | Power(KW) | Capacity(T) | Weight(T) | Size(mm) | Remark |

TYJ560-II | 90 | 1-1.5 | 6.1 | 2600*1300*2300 | Reducer Transmission |

TYJ720-II | 160 | 1.5-2.5 | 7 | 2900*1300*2400 | |

TYJ850-II | 220 | 2.5-3.5 | 14.5 | 3300*1400*3100 | |

TYJ920-II | 315 | 3.5-5 | 18 | 3800*1680*3400 | |

TYJ1050-II | 360-450 | 5-6 | 23 | 4400*1850*3700 | |

TYJ1250-II | 550-660 | 7-8 | 29 | 5100*2000*4050 |

Advantages of Vertical Ring Die Pellet machine

More Details About Vertical Ring Die Pellet Machine

Item | CE ISO Vertical Ring Die Pellet Making Machine ( TYJ Series) |

Pellet Mill Style | - With Standard or anti- arching Feeder - With or without Conditioner |

Optional Extras | - Screw feeder with anti-arching machanism - Conditioner: To adjust the moisture and evenness of raw material. |

Features | - CE & ISO & SGS - Siemens electric motor or customized, NSK/ SKF bearing - Automatic Lubrication System - Cutting mechanism |

MOQ | 1 set |

Packing Details | wood case or wood pallet etc |

Warranty | 1 year |

Payment | L/C, T/T, Western Union |

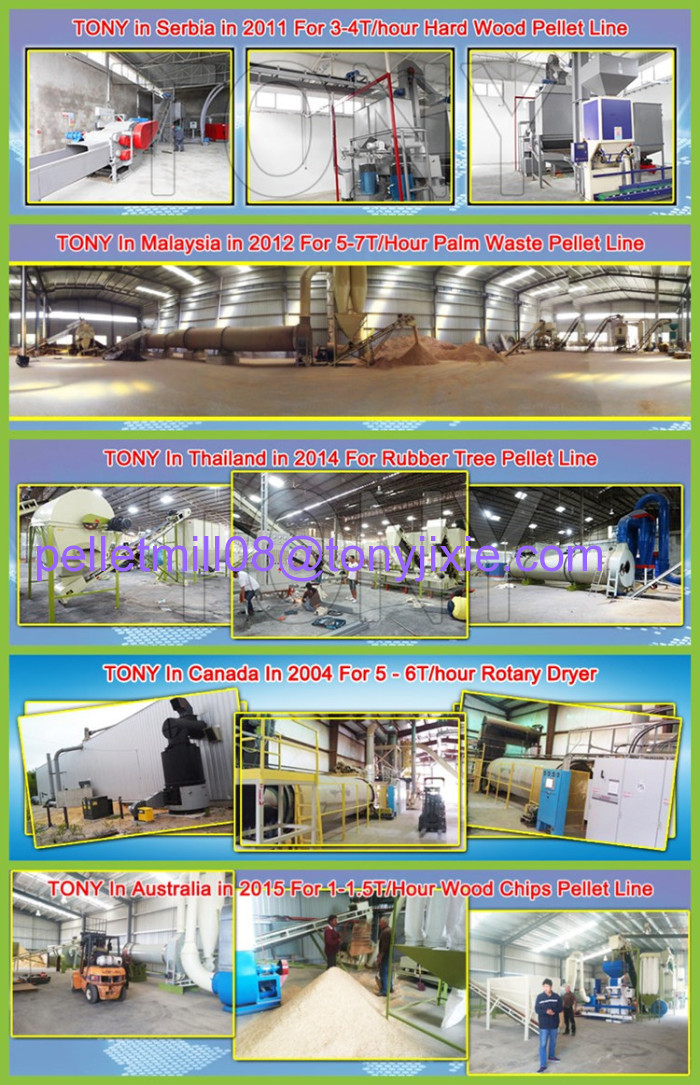

Successful Experiences Overseas | Our products have been exported to lots of Europe, South America, Southeast Asia countries, and set agents in France ,Germany, Italy, Romania, Dulgaria, Croatia, Serbia, macedinia, Switzerland, Crech and Slovakia, etc. |

Working Priciple

General Terms and Conditions

General Terms & Conditions | |

Price Term | FOB Qingdao Port, China |

Payment | 35% T/T in advance, 65% balance payment after inspection before shipping |

Delivery Time | In 30 days after receiving the confirmed order and down payment. |

Packing & Shipping | Proper packing for each unit and shipped by containers. |

Warranty | 12 months for each unit after receiving except wear parts. |

Price Valldity | 20 days from the date above, thereafter submit to our confirmation. |

Service Option | Engineers are available for oversea technical services based on mutual agreement. |

Important Informations we need to know:

A. What capacity would your prefer? -----The capacity for vertical ring die Alfalfa Pellet Millmodel TYJ550-II is 1.5-2TON per hour.

B. What is your raw material? -----According to different raw material(such as hard wood, soft wood, straw, rice hust), capacity is different.

C. What is your raw material size? -----Best size for pressing high quality pellets is 3mm.

D. What is the moisture of your raw material? -----Better to be 10-15%.

We mainly manufacture machines for pelletizing as following:

1. The SKJ Series flat die pellet mill with the volume 100kg to 4T per hour.

2. TheTY Series ring die pellet mill with the volume 800kg to 5T per hour.

3. The SKJD Series Pellet Mill with Diesel Engine with the volume 100kg to 400kg per hour.

4. The SKJT Series Pellet Mill with Tractor Engine with the volume 80kg to 400kg per hour.

5. Hammer Mill

6. Wood crusher

7. Wood chipper

8. Drum dryer

9. Packing machine

10. Whole pellet production line from the volume 0.5 ton to 20 ton per hour.

Successful Overseas Cases

For further information,please kindly contact me.

MS Jennifer Zhao

Skype: pelletmill08

Email: Pelletmill08@tonyjixie.com

Mob: +86 15854107188

www.tonyjixie.com