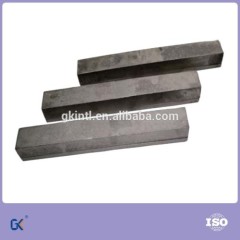

Bimetal High Chrome laminated 63HRC WEAR BAR

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 60 tons per month |

| Place of Origin: | Hunan |

Company Profile

| Location: | Changsha, Hunan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | GK-WB |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Ore |

| Type: | Feeder Machine |

| Brand Name: | GK |

| Name: | wear bar |

| Weight: | 0.9~7.3kg |

| Hardness: | 63HRC Min |

| Shearing Strength: | 210Mpa Min |

| Impact toughness: | 150J/cm2 |

| Special technique: | Heat treatment |

| Certificate: | ISO9001:2008 |

| Material: | white iron&mild steel |

| Category: | Mining Machinery Parts |

| Application: | mineral processing,recycling,mining&quarrying,sugar industry,dredging |

| Production Capacity: | 60 tons per month |

| Packing: | Wooden box |

| Delivery Date: | Shipped in 25 days after payment |

Product Description

We want to assist with your impact & abrasion challenges!

Made of the lamination of chrome moly white iron bonded to a mild steel backing plate, the Wear bars are great time savers, with the ability to patch areas on machinery and equipment to help them last longer, reduce the downtime and increase productivity.

The chrome-moly white iron with finished minimum hardness of 63HRC or 700 BHN, delivers maximum abrasion protection, while the steel backing plate absorbs high impact and facilitates ease of fitting and use.

The bonding shear strength is over 30,500 psi (or 210 Mpa) and will not separate.

Wear bar offer superior wear life when compared to conventional alloys such as managanese steel,Ni-hard and clad overlay strips.

Our Advantages

1. Alibaba's One Touch service working partner. (Less than 10 Alibaba's members in Hunan province qualified.)

2. 15 years' experience in casting.

3. Adequate capacity.

4. Thorough examinations, tracking number on each product.

Techincal Drawing:

Standard wear bars available in thickness ranging from 25 to 100mm,widths from 25mm to 300mm and varying lengths.

| Part No | Type | Size | Dimensions | Weight(kgs) | ||||

| A | B | C | D | E | ||||

| WB101 | STD | 102*33*33 | 102 | 33 | 25 | 8 | 33 | 0.9 |

| WB102 | STD | 127*51*48 | 127 | 51 | 38 | 10 | 48 | 2.4 |

| WB103 | STD | 150*50*50 | 150 | 50 | 40 | 10 | 50 | 2.9 |

| WB104 | STD | 150*75*39 | 150 | 75 | 29 | 10 | 39 | 3.4 |

| WB105 | STD | 150*75*50 | 150 | 75 | 40 | 10 | 50 | 4.4 |

| WB106 | STD | 150*75*60 | 150 | 75 | 50 | 10 | 60 | 5.3 |

| WB107 | STD | 153*38*33 | 153 | 38 | 25 | 8 | 33 | 1.5 |

| WB108 | STD | 190*50*30 | 190 | 50 | 20 | 10 | 30 | 2.2 |

| WB109 | STD | 194*80*50 | 194 | 80 | 38 | 12 | 50 | 6.1 |

| WB110 | STD | 195*25*30 | 195 | 25 | 20 | 10 | 30 | 1.1 |

| WB200 | STD | 200*25*25 | 200 | 25 | 15 | 10 | 25 | 1 |

| WB201 | STD | 203*51*20 | 203 | 51 | 12 | 8 | 20 | 1.6 |

| WB202 | STD | 210*50*50 | 210 | 50 | 38 | 12 | 50 | 4.1 |

| WB203 | STD | 230*50*50 | 230 | 50 | 38 | 12 | 50 | 4.5 |

| WB204 | STD | 241*100*58 | 241 | 100 | 38 | 20 | 58 | 11 |

| WB205 | STD | 294*80*50 | 294 | 80 | 38 | 12 | 50 | 9.2 |

| WB206 | STD | 250*60*20 | 250 | 60 | 12 | 8 | 20 | 2.4 |

| WB207 | STD | 254*50*50 | 254 | 50 | 40 | 10 | 50 | 5 |

| WB208 | STD | 254*51*20 | 254 | 51 | 12 | 8 | 20 | 2 |

| WB209 | STD | 294*50*50 | 294 | 50 | 40 | 10 | 50 | 5.8 |

| WB210 | STD | 200*75*75 | 200 | 75 | 63 | 12 | 75 | 8.9 |

| WB211 | STD | 230*50*60 | 230 | 50 | 40 | 20 | 60 | 5.4 |

| WB300 | STD | 300*25*25 | 300 | 25 | 15 | 10 | 25 | 1.5 |

| WB301 | STD | 300*38*33 | 300 | 38 | 25 | 8 | 33 | 3 |

| WB302 | STD | 300*150*60 | 300 | 150 | 48 | 12 | 60 | 21.1 |

| WB303 | STD | 300*50*60 | 300 | 50 | 40 | 20 | 60 | 7 |

| WB401 | STD | 432*50*50 | 432 | 50 | 38 | 12 | 50 | 8.5 |

| WB402 | STD | 459*38*31 | 459 | 38 | 25 | 6 | 31 | 4.2 |

| WB403 | STD | 400*43*25 | 400 | 43 | 15 | 10 | 25 | 3.4 |

| WB404 | STD | 450*38*31 | 450 | 38 | 25 | 6 | 31 | 4 |

| WB600 | STD | 600*50*50 | 600 | 50 | 38 | 12 | 50 | 11.8 |

Ingredient(%)

C | Cr | Mn | Mo | Cu | P | Si | S | Ni,B,V,Nb,etc |

2.5-3.2 | 15-18 | 1.0max | 0.5-2.5 | 0.5-1.2 | 0.05max | 1.1max | 0.05max | 0.1-0.8 |

Microstructure

Installation instructions

Please contact us for detailed cutting/welding instructions, and Video tutorials.

Application

Factory Outlook

Packaging

Sample order policy

1. We accept sample order for quality testing.

2. Sample cost required(will be deducted in your future order) and the freight collect.

The unit price will be 10~20% higher than the bulk price.

3. For regular customers, samples are free.

4. Sample lead time: 5~10 working days after sample cost received.

5. 1~2pcs sample for quality checking. Just need the shipping charge.

Contact