Copper cable granulator machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP |

| Payment Terms: | L/C, D/A, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | DY -TM 100KG 200KG |

|---|---|

| Means of Transport: | Ocean |

| Easy to operate: | Can be operated only bu 1--2 people |

| Environmental effect: | Environmental friendly |

| Function: | recycle copper wires to clean copper and plastic |

| Raw material: | waste copper wire ,waste copper cable |

| Capacity: | 150-180kg/h |

| Business type: | manufacture |

| Certificate: | CE/ISO |

| Automation: | High automation |

| Dimension: | 2700*1900*2300mm |

| Production Capacity: | 20sets/month |

| Packing: | wooden package |

| Delivery Date: | 20days |

Product Description

Cable granulator machine

Cable

granulator machine, also called scrap electric wire and cable recycling

equipment, copper wire separator, aluminium wire separator or electric

wire reparator. Copper wire recycling machine is a kind of

environmental protection machine used to recyle waste electric wire,

copper wire, aluminium wire, metallic composite wires and sheathed

lines.www(dot)copperwirerecyclingmachinery(dot)com

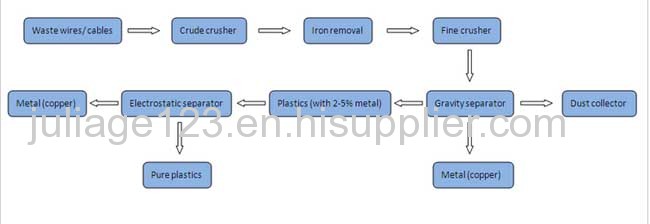

Through crude crushing, iron removal, fine crushing,

gravity separation, electrostatic separation process to make completely

dry and physical separation of scrap wires to get pure plastics and

metal for double recycling and high benefit. Equipped with the

electrostatic separator, it can make metal recovery rate get close to

100%.

Cable granulator machine working process

Working Process of cable granulator machinewww(dot)copperwirerecyclingmachinery(dot)com

Our cable granulator machine is mainly used to make the double recycling use of metal and plastics from scrap wires. The cable granulator machine through

crude crushing to extract the iron materials, then through fine

crushing to separate the metal and plastic mixture.Since the plastic and

metal granules are uniform, but the weight has big difference, they are

easy to be separated by the gravity separator. But the plastics after

separated by the gravity separator is not completely clean, may have

about 2or5% small copper wre or powder. Then use the electrostatic

separator can extract the rest and small copper wire or powder out to

get pure plastic and copper metal. Thus to increase the recycle use

value of the plastics and metals.

Cable granulator final product

Main Advantages of cable granulator machine

Our cable granulator machine adopts unique design, which has many advantages as below:

♦

Environment friendly Our cable granulator machine is a kind of

environmental protection equipment, which improved the traditional fire

buring and water washing methods which are not good for the environment.

For our cable granulator machine, there are not waste water, waste

smoke and dust pollution during the whole process.

♦ High automation -

Our cable granulator machine only needs 1-2 workers to operate. After

feeding the waste wires, the copper and plastics will be discharged

automatically. The rotate and the feeding speed can be controled by the

transducer. The motors are all copper clad motors with national

standard.

♦ High recovery rate Our cable granulator machine equipped

with electrostatic separator, the copper recovery rate can reach to

above 99.7%. Normally we can make no plastics in the copper and no

copper in the plastics.

♦ High benefitThe copper or aluminium metal

made by our cable granulator machine are very pure and clean, which can

be sold at 500 1000 RMB/ton higher than water washing and fire burning

copper metals in the market. Because the copper or aluminium after water

washing or fire burning is easy to oxidation and wastage.

♦ Durable

in use The cushers all use the hard and antiwear cutter, which is

durable and long-lasting, thus to have a long usage life.

♦ Small

land occupation Our cable granulator machine has compact structure which

require small land size. And it's easy for diassembly and installation

with convenient maintenance.

Contact: Ms Bonnie

Skype: bonniezhao2