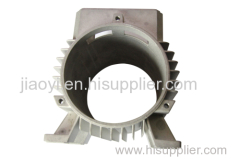

Aluminum die casting motor housing

| Min. Order: | 5000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 13000 pcs / Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Aluminum Die Casting Lawn Mower Fitting, Precision Machining Aluminum Safety Relief Valve Parts, CNC Machining Hunting Bow Aluminum Bracket, Precision Machining Auto Oil Connector Parts, Precision Machining Aluminum Valve Body Parts |

Product Detail

| Model No.: | DC-005 |

|---|---|

| Means of Transport: | Express, Ocean, Air, Land |

| Product: | Vehicle Mould |

| Product Material: | Aluminium |

| Shaping Mode: | Die Casting |

| Brand Name: | OEM |

| Surface treatment: | Shot blasting |

| Material: | ADC12 |

| Color: | Natural |

| Delivery time: | 40-50 days |

| Price term: | FOB Ningbo |

| Port: | Ningbo |

| Appication: | Motor |

| Shipment: | Air, land ocean, express |

| Packing: | Carton, wooden box or others |

| Production Capacity: | 13000 pcs / Month |

| Packing: | Carton, Wooden box |

| Delivery Date: | 40-50 days |

Product Description

| Product name | Aluminum die casting motor housing |

| Meterials: | Aluminum, Zinc,bronze, or as per the customers'requirements. |

| Dimensions: | According to customers'technical drawings or samples. |

| Surface finished: | Powder coating, |

| Sand blasting, | |

| Zinc/nickel/silver/chrome etc plating | |

| All color of anodizing,heat treatment, | |

| Polishing, | |

| As per customer's requirements. | |

| Machining equipment: | CNC machining center, |

| CNC lathe,grinding machine, Die casting machine | |

| Milling machine, | |

| Sawing machine, | |

| Turret milling-EDM, | |

| Hand punch, | |

| Automatic feeding machine etc. | |

| Test equipment: | Automatic image measuring instrument.Digital height gauge,go-no go gauge,caliper,hardness tester,roughness tester etc. |

| MOQ: | Small quantity for sample is accept. |

| Quality Control: | 100% inspection before packing or shipment. |

| Packing: | Carton,wooden box or as per customer's requirement. |

| Lead time: | 40-50 working days after receiving customer's deposit in common. |

| Payment terms: | T/T 30% deposit in advance, 70% T/T balanced against by the copy of B/L |

| Application: | Fishing Gear,Led flashlight,Valve parts,Auto parts,truck parts,machinery parts,yacht parts, |

| Hunting bow parts,bathroom hardware parts,microscope parts etc. |

Motor (Motor) is a kind of equipment for electrical energy into mechanical energy. It is through the coil is the stator windings) generated rotating magnetic field and the role of forming a magnetic force rotating torque to the rotor (such as the mouse cage closed aluminum frame). Motor by using the power of DC motor and AC motor, motor power system mostly AC motor and can be synchronous motor or is asynchronous motor (motor stator magnetic field speed and rotor rotating speed does not maintain synchronous speed). Mainly by the motor stator and rotor, direction and the direction of the current and the magnetic wire in a magnetic field in the movement of the force sensing line (magnetic field) on the direction of. The working principle of the motor magnetic force on the current role of the motor rotation.

The basic structure

The structure of a three-phase asynchronous motor, comprising a stator, rotor and other accessories.

(a) the stator (stationary part)

1, the stator core

Effect: a part of the motor magnetic circuit, and placed on the stator winding.

Structure: the stator core is composed of 0.35~0.5 mm thick steel sheet surface with insulating layer punching, laminations in the core of the inner circle of red uniform with embedded slot of stator winding.

There are several types of stator core slot:

Semi closed type slot: motor efficiency and power factor is higher, but the winding embedding and insulation are more difficult. Generally used for small low-voltage motor.

Semi open type groove: block forming winding, generally used for large and medium low voltage motor. The winding is winding can advance through insulating treatment and then into the groove.

The opening slot: to embed the winding insulation, convenient method, mainly used in high voltage motor.

2, the stator winding

Effect: is the circuit part of the motor, the three-phase alternating current to produce a rotating magnetic field.

Structure: three in space are separated by 120 electrical degrees, symmetrically arranged structure identical winding connection, each coil of these windings according to certain rules are embedded in the stator slot.

The main insulation of stator winding project has the following three types: (to ensure reliable insulation winding of each conductive part and the reliability of the core and winding insulation itself between).

The ground insulation: insulation of stator windings and stator core of the whole.

The interphase insulation: each phase stator insulation between the windings.

The interturn insulation: each phase stator winding insulation between the turns.

Motor wiring terminal box:

Motor terminal box has a wiring board, three-phase windings of the six thread arranged on two rows, and the provisions of row three wiring pile from left to right order number for 1 (U1), 2 (V1), 3 (W1), row three wiring pile from left to right order number for 6 (W2), 4 (U2), 5 (V2). The three-phase windings are connected into a wye connected or connected in a triangle. Where the manufacturing and maintenance should be in this order.

3, seat

Effect: the core and fixed before and after the stator end cover to support the rotor, and protection, heat dissipation effect.

Structure: frame is usually cast iron parts, large asynchronous motor base general welding steel plate into, the miniature motor base used aluminum pieces. Closed type motor base outside the radiating ribs to increase the heat dissipation area, protection of the motor frame at both ends of the end cover is provided with a ventilation hole, inside and outside the motor of air forced convection direct, to facilitate heat dissipation.

(two) rotor (rotating part)

1, three phase asynchronous motor rotor core:

Role: as part of the magnetic circuit of the motor and the rotor winding in the iron core slot.

Structure: the material used is the same as the stator, by the 0.5 mm thick steel sheet punching, lamination, silicon steel sheet with a uniform distribution of the hole, used to place the rotor winding. The stator core is usually used to flush the rotor core with the inner circle of the silicon steel sheet which is backward in the stator core. The rotor iron core of the general small asynchronous motor is directly pressed on the rotating shaft, and the rotor core of the large and medium-sized asynchronous motor (rotor diameter is in 300~400 mm or more) is pressed on the rotating shaft by means of the support and the rotor support.

2, three phase asynchronous motor rotor winding

(three) other accessories of a three-phase asynchronous motor

1, end cover: supporting role.

2, bearing: connecting the rotating part and not moving part.

3, bearing end cover: protection of bearings.

4, fan: cooling motor.

Two, DC motor with the use of the eight star all - fold structure, series winding, suitable for the need to reverse the automatic control technology.

Our factory:

Our workshop:

Our processing equipment:

Our Test Equipment:

Our warehouse:

Ningbo Beilun Jiaoyi Factory is specialized in CNC machining parts and die casting fitting.

We can machine include those accessories: CNC machining Lock parts, CNC machining handle parts, door and windows hardware parts, home decoration precision machining parts, CNC machining plumbing parts, precision machining building decoration parts, hardware tools parts, CNC machining bathroom parts, kitchen hardware appliances, precision machining mechanical components, furniture hardware accessories etc.

Please feel free to contact with us.and welcome to visit us at any time.